Jonas Woodhead & Sons are one of the leading manufacturers of leaf springs, parabolic springs, air suspension springs & spring Assemblies in India. They supply to OEM’s (Heavy / Light commercial vehicles), dealers and distributors across the globe.

Parabolic Springs

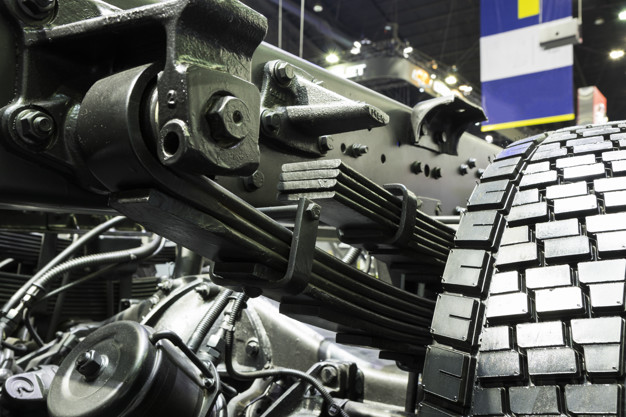

Parabolic springs consist of one or more leaves. The leaves touch only in the middle, where they are fixed to the axle and at the outer ends, where they are fixed to the vehicle. They do not touch each other in between those two points as they do with conventional leaf springs. Each leaf represents a complete spring in itself and will act as the same.To enable this, the leaf is tapered, from centre to the outer end. This parabolic rolling process means that every centimetre (or inch) the thickness of the leaf decreases in an amount that relates to the square function of its length.

Today, the parabolic spring is a bestseller and is used in most commercial vehicles. This is understandable as the easy assembly of springs leads to an almost perfect fitting accuracy with enhanced travelling comfort and more importantly a longer life cycle. The reason for a longer life is that when the springs are rolled out in the parabolic mill, they vary in thickness in turn leading to an even distribution of stress. Although parabolic springs are designed lighter and thinner than traditional multi-leaf springs they possess an improved durability and resistance. This weight reduction of approx. 35% considerably reduces the weight of the vehicle to which they are mounted. And, this in turn, reduces fuel consumption of the vehicle which compensates for the higher production costs of the spring.

parabolic springs

As markets around the world are turning to parabolic springs, the company has imported and commissioned a completely mechanized/automated parabolic rolling machine with a controlled automated end heating furnace and edge correction facility that can handle multiple reductions. This complete process is CNC controlled for precision and all its operations are managed by highly qualified engineers.

Multi Leaf Spring

Since 1963, Woodhead’s Multi Leaf Springs have been manufactured for leading OEMs across the world. Leaf springs are designed in two ways: Multi-leaf and Mono-leaf. The multi-leaf spring is made of several steel plates of different lengths stacked together. During normal operation, the spring compresses to absorb road shock. The leaf springs bend and slide on each other allowing suspension movement.

These springs are made of various grades of spring steel grades according to the design of the spring and its application.

In most cases leaf springs are used in pairs mounted longitudinally (front to back). However, there are an increasing number of vehicle manufacturers using a single transverse (side to side) mounted leaf spring.

The products are supplied to both OEMs and after-markets. As markets today are moving towards parabolic springs, the company has helped their customers around the world to establish and expand their businesses in a cost efficient manner.

Air Suspension Spring

With over five decades of experience in manufacturing suspensions Jonas has ventured into manufacturing air suspension links for OEMs.

Air suspension is a type of vehicle suspension powered by an engine driven or electric air pump or compressor. This pump pressurizes the air, using compressed air as a spring. Air suspension replaces conventional steel springs. If the engine is left off for an extended period, the vehicle will settle to the ground. The purpose of air suspension is to provide a smooth ride quality and in some cases self-leveling.

Air suspension is used to provide an adjustable suspension which allows vehicles to sit extremely low, yet be able rise to a level high enough to maneuver over obstacles and inconsistencies in the roadways (and parking lots). These systems generally employ small, electric or engine-driven air compressors which sometimes fill an on-board air receiver tank which stores compressed air for use in the future without delay.The metal spring (coil or leaf) is removed, and an air bag, also referred to as an air spring, is inserted or fabricated to fit in the place of the factory spring. When air pressure is supplied to the air bag, the suspension can be adjusted either up or down (lifted or lowered).

For vehicles with leaf spring suspension such as pickup trucks, the leaf spring is sometimes eliminated and replaced with a multiple-bar linkage. These bars are typically in a trailing arm configuration and the air spring may be situated vertically between a link bar or the axle housing and a point on the vehicle’s frame. In other cases, the air bag is situated on the opposite side of the axle from the main link bars on an additional cantilever member. If the main linkage bars are oriented parallel to the longitudinal (driving) axis of the car, the axle housing may be constrained laterally with either a Panhard rod or Watt’s linkage. In some cases, two of the link bars may be combined into a triangular shape which effectively constrains the vehicles axle laterally.

Jonas Woodhead & Sons (India) Ltd.

Manufacturers of Leaf Springs

No. 25 Vengadu Main Road,

Navalur,

Sriperumbudur 602 105.

Tamilnadu, INDIA.

+91 9791094584

contact@woodheadsprings.com

http://woodheadsprings.com/home.htm

You may also be interested in this manufacturer of #airspringsuspension #shockabsorbers #axledampers:

One thought on “Jonas Woodhead & Sons”