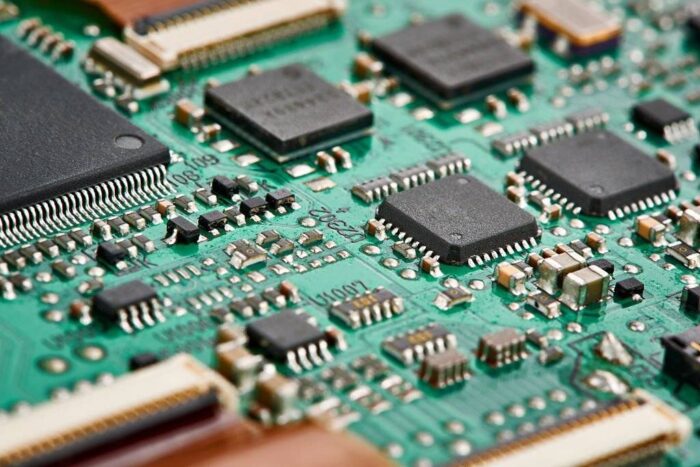

Anand Electronics supplies printed circuit boards comprised of the latest substrates, finishes and solder mask materials. They specialize both in Quickturn prototype as well as production jobs of various types, so that the customer can easily transit from design to prototype to production without any difficulty.

Printed Circuit Boards – Standard Product Types

- Quick turn prototypes – From 24 Hours

- Production – 10 Working Days

- Impedance Control Boards

- Multilayer up to 24 layers

- Flex / Rigid Flex / Flex Multilayer

- Single Side

- Double Side

- Fine Pitch Surface

- Mount/BGA

- Blind / Burried Via

- Rogers Material

- Thermal Management – Metal Core

Capabilities

| Maximum Number of Layers | 24 |

| Impedance COntrolled Boards | YES |

| Minimum Trace width/Spacing | 4Mil/4 Mil |

| Minimum hole Size | Minimum drill dia 0.2mm |

| Handling BGA Package | Yes |

| Maximum copper | 210 Microns on Tracks |

| Metal core Metal ladder PCBs | Yes |

| Maximum PCB Size | At present 460x 610mm. Can also handle larger sizes, please call to confirm. |

| Maximum PCB Thickness | 3.2mm |

| Minimum PCB thickness | 0.11mm DS or SS |

| Delivery Schedule – Protos | 24 Hours |

| Delivery Schedule – Production | 10 Days |

| Finish | SMOBC with HAL or Lead free HAL |

| RoHS ( immersion Nickel & Gold ) | |

| Solder coating | Normal boards 8 to 10 microns. |

| SMD Boards 3 Microns minimum. | |

| Standard | IPC 6012E. Also as per customer’s acceptance |

| Standards. | |

| Material Type | Double sided FR4 with Tg 130 / 170 degress. Multilayer PCB FR4 with Tg 170 degrees. |

| Please contact us for details of laminate core thicknesses / prepregs available. | |

| Edge Connector | Nickel 4-5 microns. Gold 1 micron and above(as per customer given specs.). |

| Minimum Angular Ring | 0.2mm for PTH Boards |

| 0.25 to 0.3mm for SS Boards | |

| BBT | UNIVERSAL BBT M/c- & Fly Probe Tester |

| Legend Printing | White Color or as per customer request. |

| Inputs acceptable | • Gerber files Standard gerber (RS-274D) or Extended Gerber (RS-274X). |

| • ODB++ | |

| • Netlist format IPC356 / IPC356A. | |

| • Drawings in HPGL / DXF / PDF format. | |

| • Drill data in Excellon format tool list. |

Facilities

» Pre-Engineering:

- Multiple Cam Stations

» Mechanical Finishing:

- CNC Driller / Router.

- V Scoring Machine

» Imaging:

- Dry Film Laminator.

- UV Exposure.

» Wet processing:

- PTH Line

- Pattern Plating Line

- Tab Gold plating Line

- ENIG line

- Develop Etch Strip Line

- Tin Lead Stripping Line

- Scrubber

- Deburrer

- Developing Line (Solder Mask )

- Rinser Drier

- Accumulators

» Water treatment plant

» QA/Test:

- Impedance Tester

- Automatic Optical Inspection

- Betascope

- PTH thickness measurement

- Universal Bare Board Test System

- Flying Probe Bare Board Tester

- Vernier, Screw Guages etc.

» Finishing Facilities:

- Horizontal and Vertical Solder Masking

- Converized Oven

- Hot Air Levelling System (Both Lead and Lead Free)

» Double Sided UV Curing System

» Multilayer Facilities:

- Vaccum Multilayer Press

Approvals

- ISO: 9001:2015

- UL File Number – E173304

- LCSO

- RDSO

- CDOT

- CACT

Anand Electronics & Industries Pvt. Ltd.

3/170 Krishnagiri Main Road,

Hosur-635109, TamilNadu, INDIA

Tele: 91-4344-297042, 9655111380, 9655111360, 9655111340

rfq@anand-electronics.com

jobs@anand-electronics.com

http://www.anand-electronics.com

You may also be interested in this printed circuit board manufacturer:

One thought on “Anand Electronics”