Founded in 2021, Hollowbrane Membrane Technologies (HMT) specializes in the manufacturing of Membrane Bio Reactors (MBR) and high-performance membranes, including Reinforced Polyvinylidene Fluoride (R-PVDF) and Polymeric Ultrafiltration membranes. HMT is committed to developing precision membrane filters for Sewage Water Treatment (STP) and Effluent Treatment Applications (ETP). The company offers a range of membrane solutions, including MBR membranes, Ultra/Microfiltration membranes made from R-PVDF, and Polyether Sulfone (PES) and Polysulfone (PSU) materials. Additionally, HMT designs and manufactures customized MBR, MF, UF, NF, and RO membrane filtration systems tailored to customer specifications.

HMT prides itself on its professional management team and experienced staff skilled in membrane production, design, process optimization, and project execution. The company is dedicated to ongoing research and development in product innovation and process improvement. Collaborating with internationally renowned consultants, HMT ensures cutting-edge development in its membrane technology. By closely partnering with customers and OEMs, the company provides comprehensive technical services, including process evaluation, installation, and commissioning. HMT has also partnered with leading ceramic membrane manufacturers.

Eager to work alongside water and wastewater professionals, HMT aims to tackle pollution challenges arising from rapid industrialization. Recognizing the significant market potential for MBR and other membrane separation processes in industries like water and wastewater treatment, pharma, dairy, chemical, oil, gas, and petroleum, HMT is committed to providing the best support, service, and technical solutions to advance its partners’ business endeavors.

Membrane Bio Reactors (MBR)

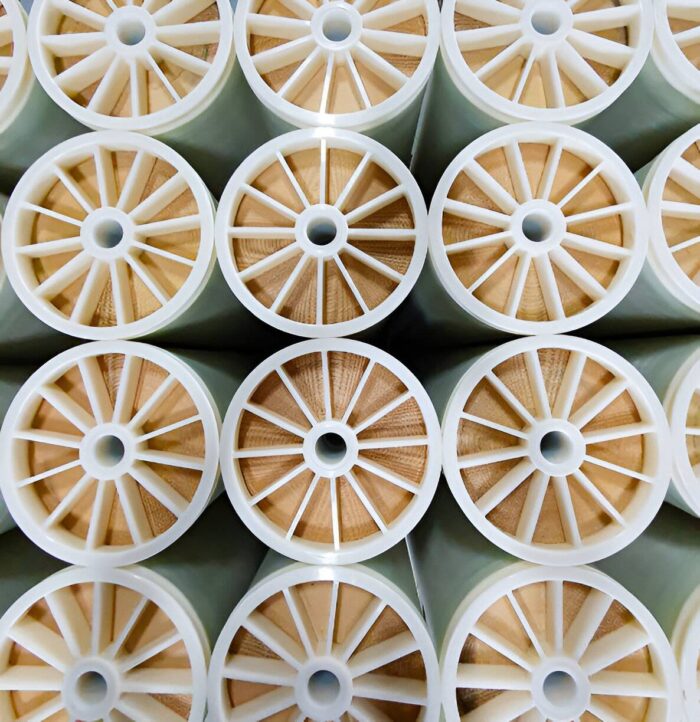

A Membrane Bioreactor (MBR) is an advanced wastewater treatment technology that combines two main components: biological treatment (bioreactor) and membrane filtration. MBRs are widely used for treating municipal and industrial wastewater to produce high-quality effluent that can be reused or safely discharged into the environment.

Components of MBR:

- Bioreactor (Biological Treatment)

- The bioreactor is a tank where microorganisms break down organic matter in the wastewater. This process is typically aerobic, meaning it occurs in the presence of oxygen.

- Microorganisms feed on organic pollutants, converting them into carbon dioxide, water, and biomass (sludge).

- Membrane Filtration

- The membrane filtration component separates the treated water from the remaining suspended solids and microorganisms.

- The membrane acts as a physical barrier, allowing clean water (permeate) to pass through while retaining bacteria, suspended solids, and other contaminants.

- Membranes used in MBRs are typically microfiltration (MF) or ultrafiltration (UF) types, with pore sizes ranging from 0.01 to 0.1 microns.

Types of MBR Configurations:

- Submerged MBR:

- The membranes are immersed in the bioreactor tank, and the treated water is drawn through the membranes using a suction pump.

- External/Side-Stream MBR:

- The membranes are located outside the bioreactor, and the wastewater is pumped through the membranes, separating clean water from sludge.

Advantages of Membrane Bio Reactors MBR:

- High-Quality Effluent:

- MBR systems produce very high-quality effluent, often meeting strict regulatory standards for reuse in irrigation, industrial applications, or discharge into sensitive environments.

- Compact Design:

- MBRs require less space compared to conventional activated sludge systems because they can operate at higher biomass concentrations.

- Reduced Sludge Production:

- MBRs typically generate less sludge compared to traditional wastewater treatment systems.

- No Need for Clarification:

- Since the membranes handle solid-liquid separation, MBR systems eliminate the need for secondary clarifiers or sedimentation tanks.

Applications of MBR:

- Municipal Wastewater Treatment: MBRs are commonly used in municipal wastewater treatment plants to meet stringent discharge standards.

- Industrial Wastewater Treatment: Many industries, such as food processing, pharmaceuticals, and textiles, use MBRs for treating high-strength wastewater.

- Water Reuse: MBRs are ideal for applications where treated wastewater needs to be reused for purposes like irrigation, industrial processes, or cooling.

Challenges:

- Membrane Fouling:

- One of the key challenges in MBR technology is membrane fouling, which occurs when contaminants accumulate on the membrane surface, reducing its efficiency and increasing maintenance requirements.

- High Energy Consumption:

- The aeration required for the biological process and the energy to drive the membrane filtration can result in higher operational costs compared to other systems.

MBR technology offers a compact and efficient way to achieve high-quality wastewater treatment, making it popular in areas with stringent environmental regulations or water scarcity concerns.

| Module Size | 10 and 15 Sq.m |

|---|---|

| Dimension (L*W*H), mm | 710*38*1172 & 710*38*1630 |

| Pore Size | 0.03 to 0.06 micron |

| Working Pressure | 0.04 MPa |

| Backwash Pressure | 0.1 MPa |

| Working Time | 8 Minute |

| Rest Time | 2 Minute |

| MLSS working range | 6000 to 12000 ppm |

Hollowbrane is an India’s first indigenous manufacturer of reinforced hollow fiber membranes for membrane bioreactor. We also provide MBR membrane elements, membrane module with SS frame Skid and compact membrane bioreactor. Our compact MBR system sizes are 5KLD, 10KLD, 25 KLD 50KLD and 100KLD. We also customize the sizes of the plant as per your requirement and site specific. Our standard membrane element dimension and features are summarised below.

HMT uses Nonsolvent-induced phase separation (NIPS) technology for manufacturing the reinforced PVDF membranes. The membranes are developed using highest quality polymers & chemicals under continuous supervision of well experienced scientific and production team. Periodic R&D is being carried out for every batch of production to optimize the membrane performance. Our R&D team continuously working for further develop of membranes. Our MBR modules specification are given below and also, we provide customised products as per customer needs.

Hollowbrane Membrane Technologies

Phase VI, No. 9, SIDCO Industrial Estate,

Maraimalai Nagar, Chennai-603209,Tamilnadu.

044-27450244, +91 9600326935

enquiry@hollowbrane.com, hollowbrane@gmail.com

https://www.hollowbrane.com/index.html

You may also be interested in this manufacturer of MBBR Sewage Treatment Plants.