Passaro is one of the leading electrical engineering consulting firms run by former employees of the state electricity board, who bring many years of experience and expertise to their consultancy services. They offer a range of services related to the design of electrical transmission and distribution systems, including EHT and HT systems and substations.

Their team is well-versed in the design of substation automation systems using PLC controls, as well as the design of auto synchronizing and auto load sharing systems for large substation DG sets. They also have extensive experience in the design of switchgear and distribution boards, and are able to offer customized solutions for a wide range of projects.

In addition to their expertise in transmission and distribution systems, they also offer comprehensive design services for medium voltage power and lighting systems, ensuring that all of our designs meet the standards of the Electrical Inspectorate of the respective state government.

They also specialize in the design of interior lighting and electrical distribution systems, using state-of-the-art cable management systems such as raceways, cable trays, and trench layouts. The team is well-equipped to design lighting and socket layouts that meet the specific needs and requirements of their clients.

They have extensive experience in the design of UPS infrastructure with redundancy systems for data centers, including the use of overhead trunking and floor raceways. They are also able to design data centers of all types, including Type A, B, and C data centers.

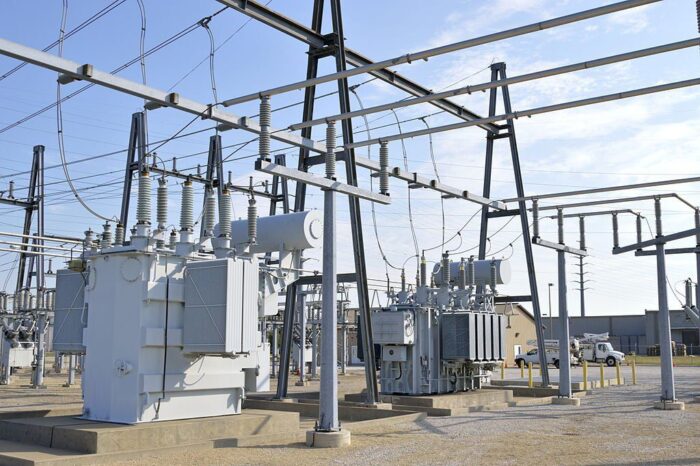

- Design of Electrical EHT and HT Transmission, Distribution Systems and Sub Stations.

- Design of Auto synchronizing and Auto load sharing of large substation DG sets.

- Design of substation automation with P.L.C. Controls.

- Design for Locations of Switchgears, Distribution Boards, etc.

- Medium Voltage Power and Lighting for any type of project as per the standards of the Electrical Inspectorate of the respective State Government.

- Design of the Interior Lighting and Electrical Distribution with State of the Art Cable Management System, raceways layout, cable tray layout, Trench Layouts, lighting layout and socket layout.

- Design of the Interior Lighting and Electrical Distribution with State of the Art Cable Management System / Over Head

- Trunking / Floor Raceways for UPS – specifications and requirements.

- Design of UPS infrastructure with redundancy system for Data Centers.

- Design of Data centers for type A, B & C.

Design of Electrical EHT and HT Transmission, Distribution Systems and Sub Stations. Electrical Engineering Consulting Firms

Electrical high tension (HT) and extra high tension (EHT) transmission systems are used to transmit electrical power over long distances, typically from a power plant to substations that are located near end-use customers. These transmission systems operate at very high voltages, typically in the range of 115 kV to 765 kV, in order to reduce electrical losses during transmission.

The design of HT and EHT transmission systems involves several key considerations, including the selection of transmission line configurations and tower designs, the protection and control of the transmission system, and the design of substations.

Transmission line configurations and tower designs:

Transmission lines are typically designed using either overhead lines or underground cables. Overhead lines consist of a conductor (usually made of aluminum or copper) supported by towers or poles, while underground cables are buried in the ground. Each type of transmission line has its own set of advantages and disadvantages, and the selection of the appropriate transmission line configuration will depend on factors such as the distance to be covered, the terrain, and the available right-of-way.

The design of transmission towers or poles is an important aspect of the transmission system, as they must be able to withstand the forces exerted by the transmission lines, as well as environmental conditions such as wind, ice, and earthquakes. Transmission towers or poles are typically made of steel, and are designed using structural analysis tools such as finite element analysis (FEA).

Protection and control of the transmission system:

The protection and control of the transmission system is critical for ensuring the reliability and stability of the power grid. Protection systems are used to detect and isolate faulted sections of the transmission system, while control systems are used to regulate the flow of power and maintain the voltage and frequency of the transmission system within acceptable limits.

Protection systems typically use sensors and relays to detect abnormal conditions on the transmission system, and to initiate appropriate protective actions such as circuit breaker tripping. Control systems may use a variety of devices such as transformers, capacitors, and reactive power compensators to regulate the flow of power and maintain the voltage and frequency of the transmission system.

Design of substations:

Substations are an important part of the transmission system, as they are used to transform the high voltage electricity transmitted by the transmission lines to lower voltage levels suitable for distribution to end-use customers. Substations are also used to switch power between different transmission lines, and to connect generators, loads, and transmission lines.

The design of substations involves the selection of appropriate transformers and switchgear, as well as the layout of the substation to ensure the safety of personnel and equipment. The substation layout may include facilities such as control rooms, transformers, switchgear, and protective equipment.

Design of Auto synchronizing and Auto load sharing of large substation DG sets. Electrical Engineering Consulting Firms

The design of an automatic synchronizing and load sharing system for large substation diesel generator (DG) sets involves several key considerations. These include the selection of appropriate control systems, the design of the power distribution system, and the selection of protective devices to ensure the safe and reliable operation of the DG sets.

Control systems:

The control system is an important part of the automatic synchronizing and load sharing system, as it is responsible for coordinating the operation of the DG sets and controlling the flow of power to the load. The control system typically includes a control panel, a synchronizing panel, and various sensors and control devices such as relays and timers.

The control panel is used to monitor the operation of the DG sets and to initiate the necessary control actions. The synchronizing panel is used to synchronize the frequency and phase of the DG sets with the power grid, and to transfer load between the DG sets as required.

Power distribution system:

The power distribution system is used to distribute the electrical power generated by the DG sets to the load. The distribution system typically includes a main distribution panel, distribution transformers, and distribution circuits.

The main distribution panel is used to distribute the electrical power generated by the DG sets to the distribution transformers, which step down the voltage to levels suitable for distribution to the load. The distribution circuits are used to distribute the power to the end-use customers.

Protective devices:

Protective devices are an important part of the automatic synchronizing and load sharing system, as they are used to ensure the safe and reliable operation of the DG sets. Protective devices may include circuit breakers, fuses, and relays, which are used to protect the DG sets and the power distribution system from overcurrents, short circuits, and other abnormal conditions.

The selection of appropriate protective devices is an important aspect of the design of the automatic synchronizing and load sharing system, as they must be able to operate correctly and reliably under a wide range of operating conditions.

Design of substation automation with P.L.C. Controls Electrical Engineering Consulting Firms

The design of substation automation using programmable logic controller (PLC) controls involves several key considerations. These include the selection of appropriate PLC hardware and software, the development of control algorithms and logic, and the integration of the PLC system with the substation’s existing equipment and systems.

PLC hardware and software:

The selection of appropriate PLC hardware and software is an important aspect of the design of a substation automation system. The PLC hardware typically includes a central processing unit (CPU), input/output (I/O) modules, and communication interfaces. The CPU is responsible for executing the control algorithms and logic, while the I/O modules are used to interface with the substation’s equipment and sensors. The communication interfaces are used to connect the PLC system to other devices and systems such as SCADA (supervisory control and data acquisition) systems, human-machine interfaces (HMIs), and other PLCs.

The PLC software is used to program the control algorithms and logic that will be executed by the PLC system. PLC software typically includes a programming language, development tools, and a runtime environment. The programming language is used to write the control algorithms and logic, while the development tools and runtime environment are used to compile and execute the control programs.

Control algorithms and logic:

The control algorithms and logic are an important part of the substation automation system, as they determine the actions that the PLC system will take in response to various input signals and conditions. The control algorithms and logic may be developed using a variety of techniques, such as ladder logic, sequential function charts, or function block diagrams.

The control algorithms and logic should be designed to ensure the safe and reliable operation of the substation equipment and systems. This may involve the implementation of protective and safety functions, as well as the control of equipment such as transformers, switchgear, and protective devices.

Integration with existing equipment and systems:

The PLC system should be integrated with the substation’s existing equipment and systems in order to ensure the seamless operation of the automation system. This may involve the development of interfaces and protocols to connect the PLC system to the substation’s sensors, actuators, and other devices.

The integration of the PLC system with the substation’s existing systems may also involve the development of monitoring and control interfaces, such as HMIs or SCADA systems, which allow operators to monitor and control the substation’s equipment and systems.

Design for Locations of switch gears, Distribution Boards, etc. Electrical Engineering Consulting Firms

The design of the locations of switchgear, distribution boards, and other electrical equipment in a building or facility involves several key considerations. These include the layout of the electrical distribution system, the availability of space, the accessibility of the equipment, and the safety of personnel.

Layout of the electrical distribution system:

The layout of the electrical distribution system should be designed to ensure the efficient and reliable distribution of electrical power throughout the building or facility. This may involve the use of electrical panels, switchgear, and distribution boards to distribute power to different areas of the building or facility.

The layout of the electrical distribution system should also take into account the location of electrical loads, such as lighting, appliances, and equipment, as well as the location of electrical service entrances and transformers.

Availability of space:

The availability of space is an important consideration when designing the locations of switchgear, distribution boards, and other electrical equipment. The electrical equipment should be located in areas that have sufficient space to accommodate it, as well as any necessary ventilation and cooling.

The electrical equipment should also be located in areas that are easily accessible for maintenance and repair, as well as for the installation of new equipment.

Accessibility of the equipment:

The accessibility of the electrical equipment is an important consideration, as it allows for easy maintenance and repair of the equipment. The electrical equipment should be located in areas that are easily accessible to authorized personnel, and should be clearly labeled for identification purposes.

Safety of personnel:

The safety of personnel is a critical consideration when designing the locations of switchgear, distribution boards, and other electrical equipment. The electrical equipment should be located in areas that are safe for personnel to access, and should be properly guarded to prevent accidental contact with live electrical components.

The electrical equipment should also be located in areas that are protected from potential hazards such as water, heat, and vibration.

Medium Voltage Power and Lighting for any type of project as per the standards of the Electrical Inspectorate of the respective Governments. Electrical Engineering Consulting Firms

Designing a medium voltage (MV) power and lighting system for a project involves several key considerations, including the selection of appropriate equipment and materials, the development of a suitable electrical distribution layout, and the compliance with relevant standards and regulations.

Selection of equipment and materials:

The selection of appropriate equipment and materials for a medium voltage power and lighting system is an important aspect of the design process. The equipment and materials should be suitable for the specific requirements of the project, and should be able to withstand the environmental conditions and loads to which they will be subjected.

The selection of MV equipment and materials may involve the consideration of factors such as voltage, current, power ratings, insulation levels, and environmental conditions.

Electrical distribution layout:

The electrical distribution layout is an important part of the MV power and lighting system, as it determines the way in which electrical power is distributed throughout the project. The electrical distribution layout should be designed to ensure the efficient and reliable distribution of electrical power, and should take into account the location of electrical loads and the availability of space.

The electrical distribution layout may include components such as transformers, switchgear, protective devices, and distribution boards, as well as conduits, cables, and other wiring materials.

Compliance with standards and regulations:

The design of the MV power and lighting system should be in compliance with the relevant standards and regulations, including those set by the Electrical Inspectorate of the respective state government. These standards and regulations may include requirements for equipment ratings, insulation levels, protective devices, and electrical installation practices.

Ensuring compliance with relevant standards and regulations is important for ensuring the safety and reliability of the MV power and lighting system.

Design of the Interior Lighting and Electrical Distribution with State of the Art Cable Management System, raceways layout, cable tray layout, Trench Layouts, lighting layout and socket layout.

The design of the interior lighting and electrical distribution system for a building or facility involves several key considerations, including the selection of appropriate equipment and materials, the development of a suitable electrical distribution layout, and the use of state-of-the-art cable management systems.

Selection of equipment and materials:

The selection of appropriate equipment and materials for the interior lighting and electrical distribution system is an important aspect of the design process. The equipment and materials should be suitable for the specific requirements of the project, and should be able to withstand the environmental conditions and loads to which they will be subjected.

The selection of equipment and materials may involve the consideration of factors such as voltage, current, power ratings, insulation levels, and environmental conditions.

Electrical distribution layout:

The electrical distribution layout is an important part of the interior lighting and electrical distribution system, as it determines the way in which electrical power is distributed throughout the building or facility. The electrical distribution layout should be designed to ensure the efficient and reliable distribution of electrical power, and should take into account the location of electrical loads and the availability of space.

The electrical distribution layout may include components such as transformers, switchgear, protective devices, and distribution boards, as well as conduits, cables, and other wiring materials.

Cable management systems:

The use of state-of-the-art cable management systems is an important aspect of the design of the interior lighting and electrical distribution system. Cable management systems are used to organize and protect electrical cables and wires, and may include components such as raceways, cable trays, and trench layouts.

The selection of appropriate cable management systems is important for ensuring the safety and reliability of the electrical distribution system, as well as for maintaining an organized and professional appearance.

Lighting layout and socket layout:

The lighting layout and socket layout are an important part of the interior lighting and electrical distribution system, as they determine the location and placement of lighting fixtures and electrical outlets. The lighting layout and socket layout should be designed to ensure the efficient and effective distribution of lighting and electrical power throughout the building or facility.

The lighting layout and socket layout should take into account the location of electrical loads and the desired level of lighting in different areas of the building or facility.

Design of the Interior Lighting and Electrical Distribution with State of the Art Cable Management System / Over Head

Trunking / Floor Raceways for UPS – specifications and requirements.

The design of the interior lighting and electrical distribution system for a building or facility with state-of-the-art cable management systems, such as overhead trunking or floor raceways, involves several key considerations. These include the selection of appropriate equipment and materials, the development of a suitable electrical distribution layout, and the compliance with relevant standards and regulations.

Selection of equipment and materials:

The selection of appropriate equipment and materials for the interior lighting and electrical distribution system is an important aspect of the design process. The equipment and materials should be suitable for the specific requirements of the project, and should be able to withstand the environmental conditions and loads to which they will be subjected.

The selection of equipment and materials may involve the consideration of factors such as voltage, current, power ratings, insulation levels, and environmental conditions.

Electrical distribution layout:

The electrical distribution layout is an important part of the interior lighting and electrical distribution system, as it determines the way in which electrical power is distributed throughout the building or facility. The electrical distribution layout should be designed to ensure the efficient and reliable distribution of electrical power, and should take into account the location of electrical loads and the availability of space.

The electrical distribution layout may include components such as transformers, switchgear, protective devices, and distribution boards, as well as conduits, cables, and other wiring materials.

Cable management systems:

The use of state-of-the-art cable management systems, such as overhead trunking or floor raceways, is an important aspect of the design of the interior lighting and electrical distribution system. Cable management systems are used to organize and protect electrical cables and wires, and may include components such as raceways, cable trays, and trench layouts.

The selection of appropriate cable management systems is important for ensuring the safety and reliability of the electrical distribution system, as well as for maintaining an organized and professional appearance.

Compliance with standards and regulations:

The design of the interior lighting and electrical distribution system should be in compliance with the relevant standards and regulations, including those related to cable management systems. These standards and regulations may include requirements for equipment ratings, insulation levels, protective devices, and electrical installation practices.

Ensuring compliance with relevant standards and regulations is important for ensuring the safety and reliability of the interior lighting and electrical distribution system.

Design of UPS infrastructure with redundancy system for Data Centers.

The design of an uninterruptible power supply (UPS) infrastructure with redundancy systems for data centers involves several key considerations. These include the selection of appropriate UPS equipment, the development of a suitable electrical distribution layout, and the implementation of appropriate redundancy and backup systems.

Selection of UPS equipment:

The selection of appropriate UPS equipment is an important aspect of the design process. The UPS equipment should be suitable for the specific requirements of the data center, and should be able to withstand the environmental conditions and loads to which it will be subjected.

The selection of UPS equipment may involve the consideration of factors such as voltage, current, power ratings, efficiency, and environmental conditions.

Electrical distribution layout:

The electrical distribution layout is an important part of the UPS infrastructure, as it determines the way in which electrical power is distributed throughout the data center. The electrical distribution layout should be designed to ensure the efficient and reliable distribution of electrical power, and should take into account the location of electrical loads and the availability of space.

The electrical distribution layout may include components such as transformers, switchgear, protective devices, and distribution boards, as well as conduits, cables, and other wiring materials.

Redundancy and backup systems:

The implementation of appropriate redundancy and backup systems is an important aspect of the design of the UPS infrastructure for data centers. Redundancy systems are used to provide backup power in the event of a failure or interruption of the primary power supply, while backup systems are used to store power for use in the event of a power outage.

The selection of redundancy and backup systems should take into account the specific requirements of the data center, including the required level of availability and the capacity of the systems.

Design of Data centers for type A, B & C

The design of data centers involves several key considerations, including the selection of appropriate equipment and materials, the development of a suitable electrical distribution layout, and the implementation of appropriate redundancy and backup systems. Data centers are typically classified into three types based on the level of availability they provide:

Type A data centers: Electrical Engineering Consulting Firms

Type A data centers are designed to provide the highest level of availability, and are typically used for mission-critical applications that require continuous operation. Type A data centers typically have redundant power and cooling systems, as well as backup systems for storing power in the event of a power outage.

The design of Type A data centers involves the selection of equipment and materials that are able to withstand the high levels of load and stress to which they will be subjected, as well as the implementation of advanced redundancy and backup systems to ensure the continuous operation of the data center.

Type B data centers: Electrical Engineering Consulting Firms

Type B data centers are designed to provide a high level of availability, but may allow for some planned downtime for maintenance and repair. Type B data centers typically have redundant power and cooling systems, as well as backup systems for storing power in the event of a power outage.

The design of Type B data centers involves the selection of equipment and materials that are able to withstand the high levels of load and stress to which they will be subjected, as well as the implementation of advanced redundancy and backup systems to ensure the continuous operation of the data center.

Type C data centers:

Type C data centers are designed to provide a lower level of availability than Type A or B data centers, and may allow for longer periods of downtime for maintenance and repair. Type C data centers typically have a single power and cooling system, and may not have backup systems for storing power in the event of a power outage. Electrical Engineering Consulting Firms

The design of Type C data centers involves the selection of equipment and materials that are able to withstand the lower levels of load and stress to which they will be subjected, as well as the implementation of basic redundancy and backup systems to ensure the continuity of operation of the data center. Electrical Engineering Consulting Firms

Passaro Electrical Consulting

87, Babu Nagar III Main Road,

Medavakkam, Chennai 600100.

Tamilnadu, India

+91 98844 80980

sales@passarotrading.com

https://en.wikipedia.org/wiki/Electrical_engineering

You may also be interested in one of the top EPC Companies in India: