Avalon Technologies based in Chennai, Tamilnadu, India is a vertically integrated manufacturing company with a product spectrum that spans System Integration, PCB Design & Analysis, PCB Assembly, Sheet Metal, Sheet Metal-Aerospace, Custom Cables & Wire Harness, Machining, Electro-Mechanical Integration, Magnetics, Injection Moulded Plastics etc

By virtue of their diversity, they are a virtual “One Stop Shop” for customers seeking holistic solutions.

The Avalon group of companies caters to multiple Industry segments such as Railways, Aerospace, Power & Energy, Communication, Medical, Oil & Gas, Automotive, Industrial and much more.

Their Capabilities: PCB Design & Analysis System Integration

System Integration

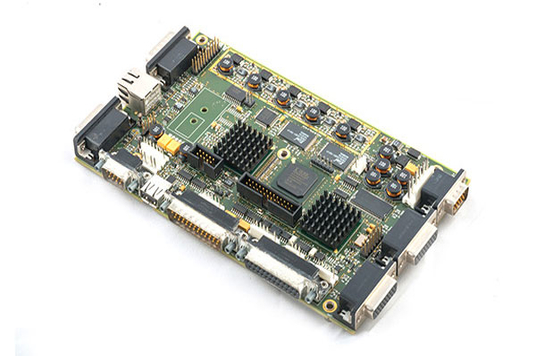

Accomplishing complete box builds, starting from assembling of the electronics, mechanics and system level assembly, software loading and product configuration including functional testing and packaging, is a competence demonstrated by Avalon across a variety of domains.

Avalon has capability for procurement, assembly, integration, testing and compliance to international standards, certified by third-party agencies.

To build, assemble and test High-Level-Assembly (HLAs) and Box builds,

MULTI-DOMAIN SYSTEM INTEGRATION EXPERTISE

- Power invertors

- Controller for industrial equipments

- Driver and automation

- GPS based equipments

- ATM machines

- Base station antenna systems

- Network, routers and server systems

- Medical devices and equipments

- Fuel dispensing systems

- Telematics modules

- In-flight entertainment systems

- HVAC systems

- Sensing and detection systems

- LRU systems

PCB Assembly

CAPABILITIES

- Hi complex double-sided PCB assembly

- High mix, low to medium volume assemblies

- 10 SMT assembly lines

- Fine Pitch SMT, through-hole and POP assemblies, Backplanes

- Automated optical inspection

- In-circuit and flying probe test

- X-ray inspection

- Full functional testing, automatic testing equipment and End of Line (EOL) testing

- Conformal coating

- IPC 610 standards class 2 and class 3

- Design for manufacturing (DFM), Design for Assembly (DFA) & Design for Test (DFT) analysis

- End to End manufacturing traceability

- Rapid prototyping

Sheet Metal

- Contract manufacture of complete medical systems, equipment and products.

- Manufacturing of enclosures for telecom, invertors, hybrid power systems, renewable energy systems.

- Enclosures, machine parts and complete box build for Railway signalling systems, Electronic interlocking systems, Point machine, Backbone telecom network (BTN), HVAC controller units, Automatic train supervision (ATS), Event recorders.

- Well-equipped internal tool room to accelerate product development and reduce Time-to-Market for our customers

CAPABILITIES

- Sheet metal fabrication – CNC/conventional

- High precision machined components – CNC/conventional

- In-house tool design and development

- Reverse engineering capability

- Complete turnkey assemblies

Sheet Metal-Aerospace

CAPABILITIES

- Skill set in manufacturing of aerospace engine parts, seating and other cabin interiors parts.

- Sheet metal fabrication (heat shields, thermal blankets, combustion liners, transition assembly, grommet & Ignitor)

- Sheet metal enclosures (power auxiliary units, power distribution)

- Precision machined components

- Sub assemblies

- Expertise with exotic material

- Metrology/material testing

- EN & Aerospace certified welders

- Value engineering

- In-house tool design and development

- Total traceability

CERTIFICATIONS

AS9100 Rev D

CEMILAC – Govt. of India has approved and certified welding process (TIG and resistance) for combustion liner parts.

NADCAP certification for welding operations.

Custom Cables & Wire Harness

TYPES OF CABLE & WIRE HARNESS

- Complex cable harness

- Coaxial and Triaxial cable

- Flat ribbon cable assembly

- RF cable assembly

- Custom wire harness

- Cable assemblies with over moulding

- Potting and Power cables

- Conduit assemble and harness braiding capability

- Electro-Mechanical assembly and panel wiring

- Impedance level testing

- IPC 620 standards

Machining

Avalon manufactures precision machined components for specialized locomotive braking systems. We manufacture bearing caps, rings, retainers, spacers, flanges, brackets and manifolds from materials such as steel forgings, aluminium extrusions and hot-rolled steel plates. We use special stainless steels & heat-resistant steel alloys & manufacture parts that go into high performance gas turbines and related power equipment

Combining precision machining services with welded frame manufacture, enclosure fabrication and systems integration provides an end-to-end integrated manufacturing service.

CAPABILITIES

- CNC Turning

- CNC Milling

- CNC Welding

- In-house special processing including powder coating, welding, EDM wire cut

- In-house tool design and development

- Reverse engineering capability

- Expertise with exotic material

CERTIFICATIONS

- ISO 9001:2015 Certified

- AS9100 Rev D

- CEMILAC – Govt. of India has approved and certified welding process (TIG and resistance) for combustion liner parts.

- NADCAP certification for welding operations.

Electro-Mechanical Integration

This is used for industrial, railway, power and aerospace applications. We have designed and manufactured racks and systems for different industry applications such as specialist heater controller cabinets and power distribution systems. Our other product line includes Electrical kits like stone crushers, signalling systems and programming units.

CAPABILITIES

- Complete system builds and full integration of multiple sub assemblies

- Custom box assemblies, consoles, cabinets, enclosures and rack-mount systems

- Electro-Mechanical assemblies

- Large scale integration of electrical and mechanical sub assemblies into final systems or products

- High-reliability soldering and assembly

- Complete testing and verification of finished products

- Full life cycle support

Magnetics

CAPABILITIES

- Toroid hook winders

- Linear traverse winding machines

- Custom transformers

- Vacuum/pressure impregnation varnishing plant

- Polarity and turns ratio tester, impulse and hi potential tester

CERTIFICATIONS

- UL 0BJY2 certified insulation system

- Traceability ensured through barcodes and batch numbers

- PPAP/FAI process in place

Injection Moulded Plastics

CAPABILITIES

- Injection moulding

- Over moulding and Insert moulding

- Ultrasonic welding

- Assembly of plastic parts and accessories

MATERIALS USED

High Performance Plastics :

ULTEM(PEI), Application : Aircraft smoke detectors PPS, Application: Gasoline products

General / Commercial Plastics :

ABS, ABS+20%GF, ABS- FR GR

General Engineering Plastics :

NYLON6, PC/ABS, PC/PBT

Avalon Technologies and

Avalon Technology & Services PCB Design & Analysis System Integration

B7 & B8, First Main Road,

MEPZ-SEZ, Tambaram,

Chennai – 600 045

Phone: +91 44 4222 0756

Mobile: +91 98842 00111

Email: sales@avalontec.com

You may be interested in this manufacturer:

5 thoughts on “Avalon Technologies”