Vens Hydroluft is a well-established manufacturer of Belt Oil Skimmers based in Chennai, India. They have a state-of-the-art facility where they manufacture their oil skimmers.

Product Range:

- Belt Oil Skimmers

- Containment Booms

- Disc Oil Skimmers

- Tube Oil Skimmers

- Floating Drum Skimmers

- Floating Funnel Skimmers

- Slotted Tube Oil Skimmers

- VOC (Volatile Organic Compound)Monitor

- Portable Vacuum System

- Rope Mop Skimmer

- Chain Oil Skimmers

- Coalescer Oil Water Separator

- Truck Mounted Vacuum System

- Grooved Floating Multi Disk Skimmer

Belt Oil Skimmers

Belt oil skimmers are devices that are used to remove oil from water using a conveyor belt. The belt is coated with a material that absorbs the oil, and as it passes through a series of rollers, the absorbed oil is squeezed out and collected in a container for disposal. Belt oil skimmers are often used in industrial settings, such as oil refineries, to remove oil from process water before it is discharged into the environment. They are also used in a variety of other applications, such as in storm water management, to remove oil and other contaminants from water before it is released into the environment. Belt oil skimmers are an effective and efficient way to remove oil from water, and they are widely used in many different industries and applications.

Containment Boom

A containment boom is a floating barrier that is used to contain and control the movement of oil, debris, or other contaminants in water. Containment booms are often used in marine environments to prevent the spread of oil spills and other water pollution. They are typically made of a flexible, buoyant material, such as high-density polyethylene, and are equipped with skirts or skirts to help keep them in place. Containment booms can be deployed around a spill or other source of contamination to form a physical barrier that prevents the contaminants from spreading. They can also be used to contain and corral debris or other floating objects. Containment booms are an important tool for protecting the environment and mitigating the impact of oil spills and other water pollution.

Disc Oil Skimmers Belt Oil Skimmers

Disc oil skimmers are devices that are used to remove oil from water using a rotating disc. The disc is coated with a material that absorbs the oil, and as it rotates, the absorbed oil is removed from the surface of the disc and collected in a container for disposal. Disc oil skimmers are often used in industrial settings, such as oil refineries, to remove oil from process water before it is discharged into the environment.

Tube Oil Skimmers

Tube oil skimmers are devices that use a tube or belt of absorbent material to remove oil from water. The tube or belt is passed through the water, and as it passes through, it absorbs the oil on its surface. The absorbed oil is then removed from the tube or belt and collected in a container for disposal. Tube oil skimmers are often used in industrial settings, such as oil refineries, to remove oil from process water before it is discharged into the environment. They are also used in a variety of other applications, such as in storm water management, to remove oil and other contaminants from water before it is released into the environment. Tube oil skimmers are an effective and efficient way to remove oil from water, and they are widely used in many different industries and applications.

Floating Drum Skimmers

Floating drum skimmers are devices that are used to remove oil and other contaminants from the surface of water. They consist of a drum that floats on the surface of the water and is coated with a material that absorbs the oil. As the drum rotates, the absorbed oil is removed from the surface of the drum and collected in a container for disposal. Floating drum skimmers are often used in marine environments to remove oil from the surface of the water in the event of an oil spill.

Slotted Tube Oil Skimmer

A slotted tube skimmer is a device that consists of a rotary slotted tube mounted on top of a tank. It is used to remove oil and other contaminants from the surface of water. As the slotted tube rotates, it collects floating scum and discharges it to drain. The slotted tube consists of 60° slots with reinforced gaps, and it can be rotated as needed using either a manual handle or a motorized arrangement. The tube is supported on one side by a closed flange and on the other side by an open flange, through which the collected scum is discharged. Slotted tube skimmers are effective and efficient at removing oil and other contaminants from water, and they are widely used in many different industries and applications.

VOC (Volatile Organic Compound) Monitor

A volatile organic compound (VOC) monitor is a device that is used to measure the concentration of volatile organic compounds (VOCs) in the air. VOCs are a class of chemical compounds that easily evaporate at room temperature and can have negative effects on human health and the environment. VOC monitors are used in a variety of settings, including industrial plants, laboratories, and homes, to measure the levels of VOCs present in the air. VOC monitors can be used to detect and quantify the presence of specific VOCs, or they can be used to measure the overall concentration of VOCs in the air. There are different types of VOC monitors, including passive monitors, which do not require a power source, and active monitors, which use a pump to draw in air for analysis. VOC monitors are an important tool for measuring and controlling the levels of VOCs in the air to protect human health and the environment.

Portable Vacuum System

Vens’ Mini Vacuum Pump is a versatile device that is designed for use in various locations, including beaches, pipelines, and industrial sites. It is capable of recovering a wide range of liquids, oils, and sludge with a minimum flow capacity of 25 cubic meters. The Mini Vacuum system consists of a vacuum head with a hopper or drum, a vacuum pump/blower, and a transfer pump. The vacuum head is equipped with a vacuum gauge, relief valve, and an automatic shut-off device to prevent the hopper from overfilling. The vacuum and transfer pumps are driven by a diesel engine or electric motor, and the system is equipped with trolley wheels for easy operation and deployment at the site. The Mini Vacuum Pump is designed to be effective and efficient at removing a wide range of liquids and contaminants from various environments.

A portable, diesel-powered vacuum unit will be provided for the suction of oils and liquids from the ground or water. The unit is designed for easy handling and movement, with a lightweight tubular frame mounted on two wheels and equipped with handles. An interconnecting hose set will also be provided. The minimum flow capacity of the unit shall be 25 cubic meters per hour. The vacuum unit is intended for use in a variety of environments and is designed to be efficient and effective at removing oils and liquids from the ground or water.

Floating Rope Mop Skimmer

Vens Rope Mop Oil Skimmer is a device that is used to remove floating oils from the surface of water. It consists of a floating rope mop that is driven over the surface of the oil by a drive unit, which also squeezes the oil out of the rope for recovery. The rope mop is made of a unique fibrillated polypropylene material that is oleophilic, meaning it attracts oil. This makes it effective at removing oils in a variety of spill cleanup and industrial applications. Vens Rope Mop Oil Skimmers have been used successfully in thousands of applications worldwide and are suitable for use in a range of climates and viscosities. They are ideal for recovering oil over small or large areas, in separators or pits, harbors, and dams.

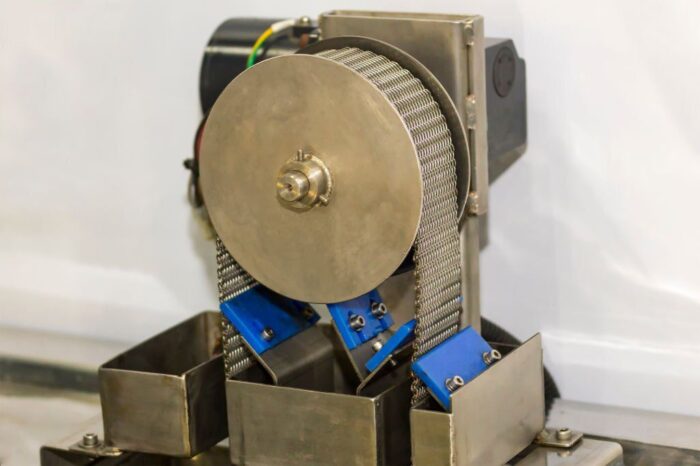

Chain Oil Skimmers Belt Oil Skimmers

The assembly consists of two parallel arrays of chains driven by sprockets with a gear reduced motor as the main power source. The chains carry a series of wiper arms that roll over the sprockets and skim the top layer of floating contaminants, which are then collected in a chamber and drained. Continuous removal of floating contaminants using this system can significantly reduce the total suspended solids, biological oxygen demand, and chemical oxygen demand load on an effluent treatment plant, resulting in reduced treatment costs upstream. This assembly is an effective and efficient way to remove floating contaminants from water and is widely used in many different industrial and environmental applications.

Coalescer Oil Water Separator

Coalescing filters or coalescers are used in industrial settings to separate fluid mixtures into their individual components. These mixtures often contain impurities such as sulfur, ethane, CO2, water vapor, and methane, which must be removed to maintain the quality of the final product. Coalescers work by using a coalescing media, a porous material that allows the impurities in the mixture to combine or “coalesce” into larger droplets that can be easily separated from the mixture. Coalescing filters are effective at removing impurities from fluid mixtures and are widely used in many different industrial and environmental applications to maintain the purity and quality of fluids.

An oil coalescer is a filtration system that is used to remove gasoline, diesel, non-emulsified oil, and other fuels from a waste stream. It works by using closely spaced oil-attracting media to promote the agglomeration of larger oil particles, which then flow up the surface of the media.

The oil coalescer is a superior separation technology that uses the principle of coalescence to remove oil and other contaminants from fluids. When two tiny oil droplets come into contact with the coalescing media, they combine or “coalesce” into a larger droplet, allowing for excellent separation of oil and water. The oil coalescer is highly effective at removing up to 95% of all floating oil from the water’s surface and is widely used in industrial and environmental applications to remove oil and other contaminants from fluids.

Coalescers are industrial devices that are used to separate mixtures or emulsions into their individual components using various methods. They can be used to separate both homogenous and heterogeneous mixtures and can be used independently or as part of a larger separating unit. Coalescers are commonly used as oil treating equipment in a variety of industries and are effective at separating oil and other contaminants from fluids. They are widely used in many different applications to maintain the purity and quality of fluids and to remove impurities from process streams.

A coalescer or coalescing filter is a device that is used to separate mixtures or emulsions into their individual components. It consists of several baffle walls or screens located at different points inside the device. When a mixture is applied to the filter, the baffles screen out the individual components by trapping them in different sections.

The separation mechanism of a coalescer is based on the molecular weight and density of the individual components in the mixture. For example, in water-oil separation, the baffle walls inside the coalescer separate the heavier oil molecules in one direction to a drain point, while the lighter water vapor molecules diffuse through the filter element and are drained out of the system by gravity.

In the case of gas-water separation, when a gas stream containing water droplets is fed through the coalescer, the water droplets diffuse through the filter element and exit through an outlet port as dehydrated gas. The heavier water molecules coalesce to form larger water molecules, which fall to the bottom of the tank for drainage. Coalescers are widely used in many different industries to separate various types of mixtures and emulsions into their individual components.

Truck Mounted Vacuum System

Truck mounted vacuums are a popular choice for industrial operations that take place outdoors or in remote areas. These industries include petroleum, wastewater treatment, sanitation, commercial aviation, agriculture, and disaster cleanup. As concerns about recycling and waste recovery have increased, truck mounted vacuum cleaners have become an important tool for retrieving raw materials from landfills and dump sites. They are an essential part of many manufacturing operations and are widely used in a variety of industries.

Vacuum trucks are versatile vehicles that are used for a wide range of purposes in various industries. They can be used to transfer liquids, clear away debris from a work location, dig holes, or assist in locating underground utility lines. While cleanup is one of their main functions, vacuum trucks are not limited to that single operation.

The inner workings of a vacuum truck include a pump that provides suction to the vacuum hose through an intake valve. As the hose begins to suck, the waste is transferred to the primary chamber of the truck. A secondary chamber is also available to prevent the waste from coming into contact with the vacuum truck’s pump as the primary chamber fills.

There are several methods that can be used to empty a truck mounted vacuum cleaner. Some trucks have a back hatch that can be opened to allow the collected waste to be dumped, while others may have a pressurized system to force out the waste. This latter method can be harmful to the equipment, so it is important to follow proper procedures when emptying a vacuum truck.

Vacuum trucks are an essential tool in a variety of applications and operations due to their mobility and versatility. They can be used to remove a wide range of waste materials and have become an important solution for cleanup and waste removal. One common use for vacuum trucks is sludge and water removal, particularly in areas where there is excess water or mud. These trucks can be used to protect infrastructure and the environment by removing and repurposing the collected water and mud.

Another important use for vacuum trucks is in the maintenance and control of sewage and septic systems in cities. These vehicles can be used to prevent overflows or leaks and to maintain the integrity of the systems. They are also helpful in reducing the burden on the systems and improving their efficiency.

In addition to these uses, vacuum trucks can also be used as part of an excavation process. They can supply water for surface removal and collect the water and debris that is removed. This process is more efficient and requires less manpower than traditional excavation methods.

Vacuum trucks are also invaluable in times of disaster, when the rapid removal of debris is critical for rescue and recovery efforts. They can be used to quickly and efficiently remove rubble and other debris, helping to protect the environment and keep survivors safe.

Overall, vacuum trucks are a vital tool in construction, environmental protection, and project maintenance, and they are used in a wide range of applications to meet the needs of various industries.

Vacuum trucks are a valuable tool for cleanup and waste removal due to their versatility, wide range of uses, and mobility. Industries that have outdoor operations are finding more and more unique uses for these trucks.

One important aspect of using truck vacuums is their ability to reduce labor hours, which helps to lower the cost of a project. In the past, it was common to hire a cleaning crew to clean large areas, but with a vacuum truck, the same job can be completed more quickly with just two operators.

Mechanized vacuum trucks are able to complete tasks such as cleanup, waste removal, waste collection, and liquid removal more efficiently than manual methods, which helps to save time and reduce the overall cost of a project. This also helps to improve the time frame for project completion.

Hydraulic Driven Floating Drum (Grooved Type) Oil Skimmer

M/s. Vens Hydroluft Pvt Ltd offers a floating drum skimmer designed to remove floating oil from water surfaces. This is an important environmental issue because floating oil can cause high levels of BOD/COD and can have negative effects on marine life if it spills over onto river, lake, or sea beds. Traditional methods of converting the oil to sludge or absorbing it with special media or booms can be costly and require frequent maintenance. The floating drum skimmer offers a more effective and efficient solution for removing floating oil from water surfaces.

VH is a leading provider of drum-type floating oil skimmers

These skimmers are ideal for large-scale removal of floating oil in various settings, including:

- Large effluent tanks in the process and chemical industries

- Oil bilges in seas, estuaries, and coastal waters

- Oil discharges in lakes, rivers, and ponds

- Refinery ETPs

- Edible oil collection tanks

- Oil cargo ports

- Crude oil production units

Vens Hydroluft,

29, Yadaval Street, Pattaravakkam,

Sidco Industrial Estate,

Ambattur, Chennai

600098, Tamil Nadu,

India.

+(91)-(44)-26231136

+(91)-(44)-26248852

+91 739 749 8659

+91 904 361 6099

You may also be interested in this Rupture Disk Assembly Manufacturer.