KMC aluminium is a Chennai based manufacturer of high-quality aluminium extrusions. KMC is an ISO/TS 16949:2009 company with it’s manufacturing facility located in Chennai.

KMC produces about 700 tons of aluminium extruded products per month which rounds up to 160 mm CCD. With the advancement in facilities, and highly qualified and trained crew KMC has been constantly striving hard to reach greater heights.

KMC has supplied aluminium to some of the most prestigious projects across the country and has built a formidable reputation as a quality supplier of aluminium extruded products.

KMC supplies extrusions for a wide spectrum of industries -not limited to but including transportation, architectural, industrial, electrical, and consumer durables industries.

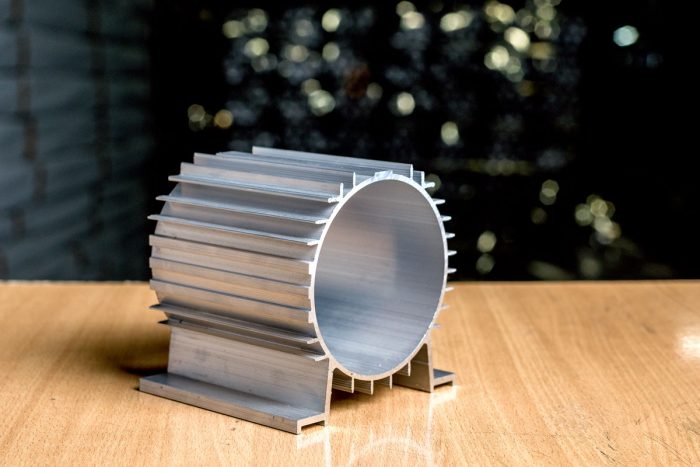

Their products have a wide range of application like A/C grills, solar panels, heatsinks, fencing, ladders, railway doors and frames & glazed surfaces for architecture.

Profile category includes round pipe, round rod, square tube, square bar, hexagon bar, rectangular tube, flat bar, radius flat bar, equal angle, unequal angle, single channel or U-channel, fluted tube and rectangular tube with C radius, AC grill, architectural, HVAC, AHU and thermal break, ladder, mesh, modular, motor body, OEM, aerospace, Power, Railways, Transport etc

Process flow @ KMC, Manufacturer of high-quality aluminium extrusions

Furnace

Furnace is where aluminum ingots or aluminum materials are melted down and molded into finished or semi-finished products by molten casting as shown in the Diagram

Billet cutting

A billet is a section of metal used for rolling into bars, rods and sections. It can be produced with ingots or directly by continuous casting. Billets are used as raw materials or extrusion processing operations.

Continuous Billet Heating

Metal billets are heated prior to forming operations (extrusion, for example). Heating the metal softens it and makes it malleable. If the metal is heated too much, then excess time and energy is used and damage can occur as extra heat is generated during the deformation process. If the billet is not heated enough, then the cool billet will be too hard to form or it may not achieve the desired hardness properties upon cooling. If the billet is too hard, it may not flow to the required shape and it may cause excessive die wear.

Die Heating Oven

Properly used, the die oven should heat the tooling to the desired temperature without regard to where each tool is placed in the oven. The tool’s time in the heater should be carefully managed: if not heated long enough the die may break; if heated too long the hardness will be lost (also resulting in breakage), and oxidation or pitting of the surfaces may occur.

Extrusion Press

Direct extrusion, is the most common extrusion process. It works by placing the billet in a heavy walled container. The billet is pushed through the die by a ram or screw. There is a reusable dummy block between the ram and the billet to keep them separated. Because of this the greatest force required is at the beginning of process and slowly decreases as the billet is used up. At the end of the billet the force greatly increases because the billet is thin and the material must flow radially to exit the die. The end of the billet(called the butt end) is not used for this reason.

Transfer Table Conveyer

A conveyor system is a common piece of mechanical handling equipment that moves materials. Conveyors are able to safely transport materials from one level to another, which when done by human labor would. It is important to note that either air compressors, vacuums, or blowers can be used to generate the air flow.

Stretching & Straightening

For the straightening of solid bars, square and rectangular tubes as well as hollow profiles, our profile straightening machines are designed especially for your application to reach an optimum straightening quality. The number of straightening rolls, as well as the number of straightening planes are adapted to the profiles to be processed. For square and rectangular tubes, straightening machines with adjustable straightening rolls’ pitches are used.

Cutting

It has a feature of easy operation, reliable performance, advanced technique and convenient maintenance.

The profile cutting size adopts the digital display technique to ensure high efficiency and accuracy.

Imported carbide saw blade gives accurate processing and high efficiency.

Two cutting heads can work together or single, when together work, one time can cut off the required length and angle.

It’s a high efficiency cutting machine for aluminium window and door profiles, industrial aluminum profiles and curtain wall aluminium profiles, aluminum ladder profiles etc..

Ageing

The aluminum profile should be carried out aging treatment after extrusion, the purpose is to improve the intensity of the aluminum alloy shape and benefit to operation, storage and transportation for the after extrusion procedures, and also for normal usage of the clients. Technical Process:190 ℃ ~ 195 ℃ for keep warm about 3.5 hours, and then adopt the forced-air-cooling process.

KMC Aluminium Pvt Ltd Manufacturer of high-quality aluminium extrusions

Corporate Office

No:3, Eswar apartment 1st floor,

2nd main road, United India Colony,

kodambakkam, Chennai-600025.

044-42618533

Factory

Plot No: C-13, SIPCOT Industrial Park,

Irugattukottai, Sriperumbudur,

Chennai, Tamil Nadu 602105

044-27156212 / 14 / 17

marketing@kmcaluminium.com