G Plast Pvt Ltd – An IATF 16949, ISO 14001, ISO 45001, AS9100D & ISO 13485 Certified Company based in Tamilnadu, India, With four decades of experience and expertise in Tool & Die making, soft tooling, Injection Molding and Die Casting, it’s a part of the UMS Group well known for its achievements in Electronics, Precision Machine Tools and Transport.

Their services include:

- 3D Cooling/Additive Manufacturing

- Rapid Prototyping/Soft Tooling

- Tool Design & Manufacturing

- Injection Molding

- Pressure Die Casting

- Precision Machining & Secondary Operations

- Sub-Assembly

3D COOLING/ADDITIVE MANUFACTURING

Laser CUSING® Technology of layer-by-layer construction of metal powder helps to produce near to 100% dense Components. A method of manufacturing Metal Prototypes (Direct Metal Parts) for the Product Development & Batch parts production to save Time & Cost. This process can be widely used for various industries like Aerospace, Automotive, Medical, Precision part manufacturing, Consumer product manufacturing, Mould manufacturing (Plastic & Die casting), Jewellery etc.

Laser CUSING® allows the user to have Tooling inserts with Internal Features (Conformal/3D Cooling). This improves the aesthetics & dimensional accuracy of the Component.

Fusion of single-component metallic powder materials: This method allows the layer-by-layer construction of components from almost all metallic materials (e.g., stainless steel and hot work steel powders). Metallic powder is hereby fully fused layer for layer to produce a 100% component density.

RAPID PROTOTYPING/SOFT TOOLING

With a close association with trusted vendor networks, they undertake rapid prototyping work to produce parts in Plastic materials, Using SLA, SLS & Vacuum casting process Painting and Printing work also done as per customer requirements.

Laser Sintering provides rapid prototypes that are the working representations of the most complex designs. Laser Sintered prototypes can be subjected to functional testing.

TOOL DESIGN & MANUFACTURING

With Four decades of expertise, the company has developed more than 3,700 Tools in-house for global business needs. Design solutions offered by G PLAST always delight the customers. Equipped with latest design software along with flow analysis for injection moulding and high-pressure die-casting.

Reverse Engineering:

For customers G-Plast provides reverse engineering service to produce data which can be used for further development.

Design of Injection moulds and Die casting dies:

Design of moulds and dies are based on the input given by customers in the form of 2D drawing and 3D model. Also, the design is taken up considering Customer Specific Requirement (CSR). Flow Analysis also considered to finalize the tool design.

CAM Programming:

The Design Centre is capable of generating CAM Programs for Machining Centres (3-Axis & 5-Axis), WEDM.

INJECTION MOULDING

G Plast, a custom injection moulding company serves to various sectors like Automotive, Aerospace, Medical, Electronics, Home Appliances, Telecom etc.

They offer an uncompromising commitment to their customers on quality delivery and meeting their standards. Materials handled include PC, POM, PA6 , PA66, PA46, PPS, PMMA, PEI (ultem), ABS, PP, PBT, PSU, TPU, SS filled PC, etc… They process the materials upto 50% fillers like carbon fiber, glass fiber, glass beads, talc.

Plastic Injection Moulding:

Total of 20 Injection Moulding machines up to 550T capacity including ARBURG universal all rounder, ENGEL, LTM Demag, Super Master, Windsor and Fanuc All Electric.

Insert Molding:

G Plast has been doing insert moulded parts for various applications using bearings, sheet metal, pins & bushes and die-casted parts in both vertical and horizontal moulding. We specialize in Vertical and Horizontal Insert Moulding.

Foam Molding:

Foam molding is done effectively and efficiently for its typical advantages like improved strength to weight ratio, reduced shrinkage and good dimensional stability etc.

Encapsulation:

We also handle wound coils Insertion effectively by injection moulding.

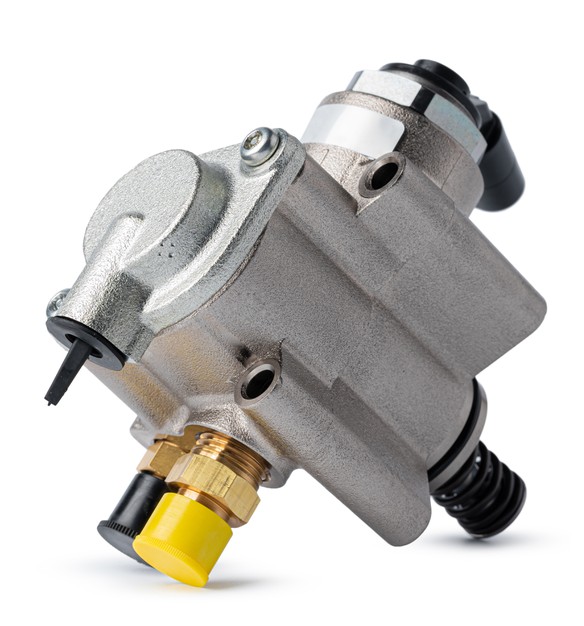

PRESSURE DIE CASTING (SOFT TOOLING AND INJECTION MOLDING COMPONENTS)

G-Plast’s Die-Casting shop caters to Automotive, Computer Peripherals, Pneumatics, Aerospace, Textiles, Oil & Gas & General Engineering, etc… General Engineering Industries having capability to supply Aluminium & Zinc Die-Casting parts.

Casting, online trimming, secondary operations including vibro finishing, shot/sand blasting, ultrasonic cleaning, impregnation, leak testing (upto 50bar), machining and painting/surface coating. Sub assemblies are also handled based on customer requirement.

They are also exporting parts to Super-Markets directly. Complex Die Cast Components for engineering applications are mass-produced and supplied in Ready-to-assemble condition.

Equipped with 10 Machines ranging from 80T to 350T for Aluminium (Including Frech 350T). Frech 125T Hot Chamber machine supports processing of Zinc parts. Precision Machine Shop takes over the secondary machining to finish the parts.

PRECISION MACHINING & SECONDARY OPERATIONS (OF SOFT TOOLING AND INJECTION MOLDING COMPONENTS)

The machine shop is specialized in handling Medium & High-volume parts using an innovative clamping system which enables frequent change-over of Jobs.

5-Axis Machining Centre from Hermle & HURCO, 3-Axis Machining Centre from Makino, Haas, Romi and an array of Lathes from GEDEE Weiler (Group Company) to perform intricate turning jobs are in operations at our facility, with Robotic Assistance

Special Purpose Machines (SPM) are used to meet out customer’s Specific Requirements.

Investment in the latest technology and know-how always keeps us in the competitive edge to provide challenging machining solutions to the market.

Secondary operations including vibro finishing, shot/sand blasting, ultrasonic cleaning, impregnation, leak testing (upto 50bar), machining and painting/surface coating. Sub assemblies are also handled based on customer requirement.

SUB-ASSEMBLY OF SOFT TOOLING AND INJECTION MOLDING COMPONENTS:

G Plast’s Sub-Assembly Shop with well organized production lines is a supportive facility to our Die-casting Division to produce completely assembled Parts.

This gives an added advantage to all the customers who look for a complete solution under One Roof.

The Production lines are capable of precision assembly of metal parts offering a fast turnaround service. Hence the desired output is achieved at the end of the day resulting in customer satisfaction.

In addition to In-house finishing operations, G Plast also works with certified subcontractors providing high specification coatings with limitless choice of colours and finishes (like Anodizing, Chromating etc).

G-Plast Pvt. Ltd., (Unit I)’ Soft Tooling and Injection Molding

No.1065, Gopal Bagh,

Avinashi Road,

Coimbatore-641018.

Phone:

+91 422 4321300

+91 422 2243439 (5 lines)

Fax:

+91 422 2242760

G-Plast Pvt. Ltd., (Unit II) Soft Tooling and Injection Molding

No-83 A, Civil Aerodrome

Post, Avinashi Road,

Coimbatore-641014.

Phone:

+91 422 2570369

+91 422 2598774

Fax:

+91 422 2242760

marketing@gplast.com

info@gplast.com

http://www.gplast.com/index.php

You may also be interested in these service providers:

2 thoughts on “G Plast”