Established in 1981 as a joint venture with BS&B Safety Systems Inc, USA, this company is one of the leading rupture disk, rupture disk assembly manufacturers.

BS&B Safety Systems (India) has been manufacturing, marketing and servicing the Indian industry now over 4 decades. BS &B Safety Systems has been a world leader in pressure relief technology for over 9 decades.

Product Range:

- Rupture Disks Devices

- Industrial Explosion Protection

- Custom Engineered Products

- Flame Arresters

- Specialty Valves

Rupture Disks Devices Rupture Disk Assembly Manufacturers

Invented by BS&B, their range of reverse buckling products provides a pressure relief solution for burst pressures ranging from a few inches of water column / a few millibar to over 70,000 psig / 4800 bar.

Sta-Saf® Systems

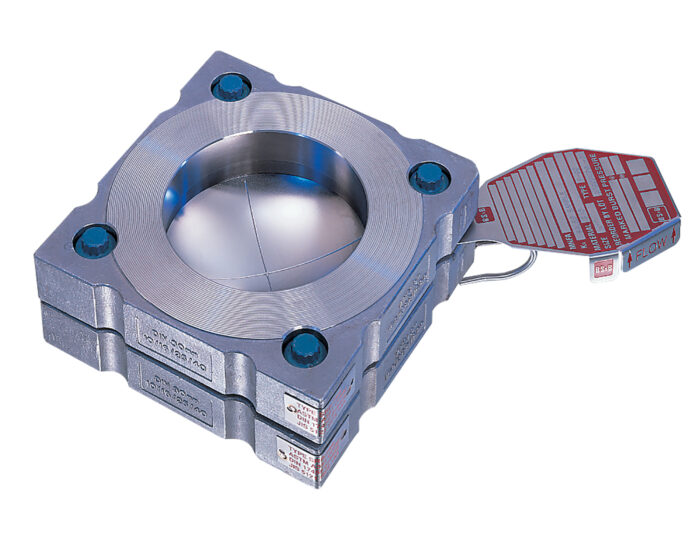

The Sta-Saf® system is the combination of solid metal reverse buckling disks with pre-torqued safety heads.

Standard features:

- Operating ratio up to 100% (CE) / 95% (ASME)

- Full vacuum resistant

- SRB-7RS and SRB-7FS pre-torqued safety heads

- Solid metal construction enabling optimum leak tightness

- Designed for non-fragmentation

- Recommended for isolation of pressure relief valves

Alternative reverse buckling devices

Standard features:

- Operating pressure to 90% of the marked burst pressure

- Designed for gas, liquid or multi-phase flow conditions

- Lowest burst pressure in a reverse buckling style disk

- Optimum fatigue resistance in pressure pulsating or cycling conditions

- Designed for non-fragmentation

- Ideal for relief valve or tank vent isolation

Vac-Saf® Rupture Disks (Two – way relief)

Standard features:

- The Vac-Saf ® system offers twoway relief to provide maximum protection of gas or liquid storage vessels and plant from damage caused by excessive vacuum or overpressure.

Sanitary Rupture Disks

Designed with a circular score line located at the edge of the domed area which is used for hygienic/aseptic applications in the pharmaceutical, biotechnology and food industries

Standard features:

- One disk design for both gas and liquid service

- Wide range of pressures

- Ideal for CIP / SIP service

- Integral sanitary gaskets

- Suitable for operating pressures up to 90% of marked burst pressure* or 95% of the specified minimum burst pressure

- Withstands full vacuum at all available burst pressures

Forward Acting Tension Loaded Disks

Standard features:

- Tension loaded, forward acting.

- Flange type installation in BS&B type FA-7R safety heads for installation between companion flanges.

- High burst pressure capability

- Gas or liquid service.

- Maximum operating pressure – 70% of marked burst pressure

- Threaded union type installation in BS&B type UA safety heads

Saf-T-Graf® Monobloc and replaceable element Graphite Disks

Standard features:

- Convenient, Economic, Corrosion Resistant Graphite disks are made from impregnated graphite offering low burst pressure and excellent corrosion resistance.

- BS&B graphite disks are supplied with integral gaskets for direct installation between international pipe flanges.

- The replaceable element range is installed in graphite or stainless-steel safety heads before installation between pipe flanges.

- A steel armoring ring around the disk for added safety and easier installation is recommended.

- 0.5-24 inches (15-600mm)

- Burst pressures 0.25-1,000 psig (0.02- 69barg)

- Temperatures to 400°F (205°C) – higher operating temperatures to 800°F (427°C) are achieved using a ‘high temperature assembly’

Burst Alert Sensors

Standard features:

- Reduced Inventory Costs. One head fits most standard international flanges eliminating the need to stock unnecessary and costly inventory.

- Simple, Fail-Safe Installation. The asymmetric locating pins and standard welded J-Bolt ensure correct orientation by eliminating possible human error.

- Leak-Tight Bite-Type Seal. BS&B is the only disk manufacturer who machines a Bite-Type seal into the inlet flange of the Safety Head that engages the disk material proper creating a bubble-tight seal.

- Easy Cleaning and Inspection. Maintenance can be done without replacing the disk due to the pretorqued cap screws, which maintain the clamping load on the disk.

Explosion Protection Rupture Disk Assembly Manufacturers

Common industrial processes have the potential for a dust explosion. Where combustible material is conveyed, filtered, heated, milled, or sprayed in a fine powdered form, the three elements of the ‘explosion triangle’ can combine: dust + air + ignition.

Explosion Venting (Vent-Saf® and Vent-Saf® Plus)

Standard features:

- Designed to protect equipment against damage in the event of deflagration of combustible materials

- Explosion panels are low burst pressure membranes which are designed to be fastened over an opening of calculated size to provide rapid pressure relief

- BS&B utilizes NFPA 68, EN 14491, and VDI-3673 venting guidelines, which are recognized worldwide

FlameFree™ – Explosion venting

Standard features:

- Certified and tested to different international standards

- For indoor installations and on outdoor process with restricted evacuation options.

- High venting efficiency

Explosion Suppression and Chemical Isolation Systems

Standard features:

Type IPD system – explosion suppression and isolation systems detect the earliest stage of a deflagration by sensing the pressure wave that comes ahead of the flameball and uses the signal to activate delivery of an extinguishing agent

A typical system consists of the following:

- Sensor

- Power supply module

- System monitor

- Several explosion suppression ‘cannons’

Custom Engineered Products (CEP)

Their design engineers are ready now to work with you. From a single custom designed component to a high-volume application, their design experience and manufacturing support capabilities are ready to meet your challenge!

Standard features:

“Combining Custom with Economy”

- A wide range of standard and custom designed rupture disk assemblies are available for your specific application

- Assemblies are designed to be discarded after disk rupture; other designs permit the replacement of the ruptured disk

- Customized designs are available for customer applications which cannot be met using standard assembly designs

- 1/8-6 inches (3-150mm)

- Burst pressures from 1-100,000 psig (0.07-6,900barg)

- Disk assemblies include soldered, welded, crimped and threaded designs

Flame Arresters

Flame arresters stop the transmission of flames through piping after an ignition event associated with combustible gas inside the piping.

In-Line Deflagration/Detonation Flame Arresters

Standard features:

- Flame arresters are used as secondary protection against explosions by preventing the transmission of flame and explosion transfer in machines, equipment and plant, containing inflammable gas or steam-air mixtures of inflammable liquids.

- These autonomous safety systems limit the effects of the explosions, rendering them harmless, they are intended to allow flow but prevent flame transmission

End-of-line Deflagration

Standard features:

- Flame arresters are used as secondary protection against explosions by preventing the transmission of flame and explosion transfer in machines, equipment and plant, containing inflammable gas or steam-air mixtures of inflammable liquids.

- These autonomous safety systems limit the effects of the explosions, rendering them harmless, they are intended to allow flow but prevent flame transmission

Safety Components

Standard features:

- Flame arresters are used as secondary protection against explosions by preventing the transmission of flame and explosion transfer in machines, equipment and plant, containing inflammable gas or steam-air mixtures of inflammable liquids.

- These autonomous safety systems limit the effects of the explosions, rendering them harmless, they are intended to allow flow but prevent flame transmission

Specialty Valves

Buckling Pin technology offers an accurate and reliable means of calibrating pressure relief devices. BS&B has developed the BPRV™ Buckling Pin Relief Valve for in-line pressure or vacuum relief offering quick and simple external resetting.

Buckling Pin Pressure Relief Technology

Standard features:

- Fast acting, quick opening buckling pin activation pressure relief devices designed to protect personnel, equipment and the environment from danger of over pressure

- Ability to ‘field-reset’ while remaining installed after an over pressure event.

BS & B Safety Systems

147, Karapakkam Village,

Chennai – 600 097,

Tamil Nadu, India.

+ 91 44 2450 4200

+ 91 44 2450 2124

bsb@sanmargroup.com

http://www.bsbsystems.in/index.html

You may also be interested in this pure steam generator manufacturer:

One thought on “BS & B Safety Systems”