IGP is a leading manufacturer and exporter of all types of industrial gaskets. The group’s manufacturing facilities are spread over 13 factories. These factories use state of the art manufacturing techniques and are equipped with up-to-date testing facilities to provide good quality products.

Product range includes:

- Spiral Wound Gaskets

- Ring Gaskets

- Solid Metal Gaskets

- Non-Metallic Gaskets

- Insultation Kit Gaskets

- Heat Exchanger Gaskets

- Kammprofile Gaskets

- Monolitihic Insulation Joints

- Valve Components

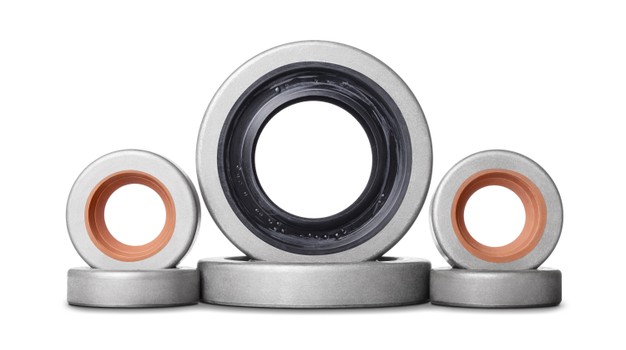

SPIRAL WOUND GASKETS

Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical and arduous duties. Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets.

These gaskets are manufactured to International specifications such as BS, API, ASME, DIN. We also manufacture to customer’s specifications

Available in several standard shapes

SWR Spiral Wound Metaillic Gasket without centering ring

SCD Spiral Wound Metallic Gasket with centering device

SOR Spiral Wound Metallic Gasket with centering ring. (Centering ring made of carbon steel stainless steel and other metals)

SIO Spiral Wound Metallic Gasket with inner & outer rings. (Rings are made of carbon steel stainless steel and other metals)

SIOH Spiral Wound Metallic Gasket with outer ring supplied with bolt holes and inner rings

SIR Spiral Wound Metallic Gasket with inner rings. (Rings generally of stainless steel)

Spiral Wound Metallic Gasket ‘W’ type and Spiral Wound Metallic Gasket ‘Inverted W’ type are also available.

FLANGE STANDARDS

ASME/ANSIB16.5 MSS SP44 (ASME B16.47 SERIES A) (AWWA)

BS 1560, BS10, BS4504 DIN FLANGES, JIS FLANGES

API 605 (ASME B16.47 SERIES B) FRENCH NF STANDARD

RING GASKETS

Ring Gaskets are designed to seal by “initial line contact” or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the softer metal of the gasket flows into the imperfections of the harder flange material, creating a very tight and efficient seal.

Standard Ring Gaskets

Standard Style R Ring Gaskets are manufactured in accordance with both API 6A and ASME B16.20 size/ratings. Available in both oval and octagonal configurations, both types are interchangeable on the modern octagonal type grooved flanges.

R TYPE – OCTAGONAL

The Octagonal cross section has a higher sealing efficiency than the Oval cross section and is therefore preferred. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

R TYPE – OVAL

The oval section ring gaskets were originally designed for the now obsolete round bottom groove. Both the Oval and the Octagonal cross section are interchangeable on the flat bottom groove design. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

BX TYPE RTJ

BX Ring Gaskets are designed for pressures up to 20,000 psi, suitable only for use with API type BX flanges and grooves. The gasket has a square cross section with beveled corners. All BX sizes have a pressure passage hole to equalize pressure across sealing surface.

RX TYPE RTJ

The RX is a pressure energized version of “R” type flat bottom groove. RX Ring Gaskets are designed for pressures up to 5,000 psi, they are pressure activated ring gaskets designed to use the fluid pressure to increase sealability. These gaskets are manufactured as per API 6A / ASME B16.20 to suit API 6B and ASME B16.50 flanges.

SUBSEA GASKETS

IGP is able to provide safe, dimensionally and functionally interchangeable subsea wellhead, mudline and tree equipment within the scope of API. The performance requirement of pressure integrity, thermal integrity, material choice along with no observable leakage allowable are met with these sealing desires. To distinguish from topside Ring Type Joints the suffix “s” is used to indicate the additional pressure passage hold in the ring cross section. This is to indicate the additional requirement to prevent pressure lock when connections are made up underwater.

IX Seal Ring

IX Seal Ring IX Seal rings are designed to be used in Norsok Compact Flange connections (NCF). Available in different materials, IX rings are supplied with colour coded PTFE coating to denote base material supplied. Identification markings are on the inside of the ring in accordance to NORSOK L-005 standard.

LENS RINGS

IGP Lens Rings, manufactured in accordance with DIN 2696. Lens Rings have a spherical surface and are suitable for use with conical flange faces (other styles are available on request).

RUBBER COATED RING TYPE JOINTS

This is Ring Gasket totally enclosed in a nitrile rubber coating. The Ring Gasket material is usually soft iron or low carbon steel. This type of gasket has three main functions:

It is used in pressure testing to minimize damage to flanges.

The rubber contact points provide additional seals while protecting the flange surfaces.

It provides increased assurance against corrosion, which can occur between conventional Ring Gaskets and the engaged surfaces of the groove. A wide range of standard sizes are available, with special sizes available upon request & and are not involved by the API specification.

SPECIALIZED RING TYPE JOINTS

For critical and non-standard applications, IGP offers a range of specialized Ring Gaskets to suit the needs of the petrochemical industry.

TRANSITION RING GASKETS:

These are combination rings which consist of two different sizes having the same pitch circle diameter. They are used for sealing Ring Gasket flanges where the mating flanges have different ring groove diameters. Transition Ring Gaskets can be manufactured from standard materials, as well as high nickel alloys. Transition Ring Gaskets are available with either oval or octagonal facings and are not involved by the API specification.

SOLID METAL GASKETS

Solid metal gaskets are used in applications where temperatures and pressures rule out the use of traditional gasket materials. In general, gasket compression loads need to be high to deform the gasket, and the metal used for the gasket should be softer than the metal in the mating surfaces.

MATERIAL OF CONSTRUCTION

Carbon Steel, Stainless Steel 304,304L, 316,316L,316Ti,321,347, Monel® 400, Inconel® 600,625,800, Incoloy 800, 825, Nickel 200, Titanium, Hastelloy, Copper.

SPECIFICATION

As per Customer Requirement.

SIZE

As per Customer Requirement

SHEATHING MATERIAL

Graphite, PTFE etc.

NON-METALLIC GASKETS

At IGP, we manufacture Non-metallic gaskets to ASME, JIS, BS, DIN & other international standards. We specialize in meeting the unique needs of customers. Commonly used materials are

Natural and Synthetic rubber

PTFE

Compressed Asbestos

Fibre cork

Woven Asbestos

Graphite

Non asbestos Aramid fibre

FERRULE GASKETS

These are non metallic gaskets with an inner protection to prevent direct contact with the fluid handled. The material used for the gasket is like any other non matallic gasket. The inner protection is provided with SS Ferrule.

Rubber Gasket

Rubber Gasket

Graphite Gaskets

Graphite Gaskets

Prev

Next

RUBBER OR ELASTOMERIC GASKETS

We can Supply all types of Elastomeric Gaskets made of Natural Rubber, Neoprene, Nitrile, EPDM, Butyl, Polybutadiene, Silicon, Flourocarbon, Chlorosulphonated Polyethylene, Styrene Butadiene Rubber etc.

These rubber gaskets could be supplied

In colors like black & white or red. With or without Fabric or Metal reinforcements. Reinforcements are provided with the help of wire mesh or metal or natural or synthetic fabrics depending on the specifications and thickness suitable to service conditions. They are suitably molded to all flange dimensions as full face, flat face and blind gaskets.

Our Rubber Gaskets have been used in Petroleum Refineries, Process Industries, Food Processing units etc.

RUBBER MATERIAL PROPERTIES

Material Temperature Range High Resistance

Natural Rubber(NR) 60 C Water,air and average concentration acids,bases and salts. Good abrasion resistance.

Neoprene(CR) 80 C Moderate acids and chemicals,Ozone, Oils,fats and Solvents. Used in Oily abrasive applications.

Nitrile(NBR) 110 C Most Hydrocarbons ,Fats,Oils,Greases,Hydraulic fluids, Chemicals and solvents.

EPDM 120 C Vegetable and animal fats, oils,ozone,many strong oxidising chemicals,ketones and alcohols.

Butyl (IIR) 120 C Animal and vegetable oils, fats,greases,air,gas, water,many oxidising chemicals and ozone.

Hypalon (CSM) 120 C Strong acids and bases,Freons hydroxides, ozone, Alcohols, etching,Alkaline and Hypochlorite solutions.

Viton(FKM) 200 C Aromatic Aliphatic and halogenated hydrocarbons, acids, animals and vegetable Oils

Silicon 150 C Moderate or Oxidising chemicals, ozone, concentrated Sodium Hydroxide

Styrene Butadiene Rubber (SBR) 60 C Water,Air,Anti-Freeze detergents, Salt solutions ,Bases, Alcohols and some acids.

INSULATION KIT GASKETS

“Spiraget®” Flange Insulation Kit Gaskets are designed to combat the effects of corrosion often found in flanged pipe system. Galvanic corrosion between dissimilar metal flanges, flange insulation associated with cathodic protection of underground piping are other examples where “Spiraget®” flanges insulating Kit Gasket can be put to effective use.

The Design and selection of materials used in “Spiraget®” Flange Insulation Kit Gasket, meet the twin purpose of sealing the flanges and insulating metal parts to prevent flow currents responsible for corrosion.

“Spiraget®” Range: Insulation Kit Gasket

We design, manufacture & supply Flange Insulating Kit Gasket in three types:

TYPE-E for full face flanges

TYPE-F for raised face flanges

TYPE-D gaskets specifically designed to fit into the grooves of RTJ Flanges

Flange Insulation Kit Gasket will comprise of:

For Type “E” and type “F”

One central gasket of suitable thickness in flat section

One full length insulating sleeve per bolt / Integral Washer Sleeve

Two insulating washers per bolt

Two electro plated metallic washers

Insulation Kit Gasket 02

Insulation Kit Gaskets

“Spiraget®” Insulation Gaskets for Type “F” Raised Face Flanges

Available for use in ANSI B16.5, API, BS & DIN Standard. In this type, the central gasket is designed to be located inside the flange bolt circle and sits fully on the raised face portion of the flange. This type of gaskets will be supplied in all the materials as shown in “Materials Used ” Table below.

“Spiraget®” Insulation Gaskets Type “E” for Full Face Flanges

Available for use in ANSI B16.5, API, BS & DIN Standard.

In this type, the central gasket has its outside diameter as equal to that of flange outside diameter and precision cut bolt holes. This design helps easy alignment of the gaskets during installation. Type “E” gaskets are available in Neoprene faced reinforced phenolic material or other materials as shown in “Materials Used ” Table below.

“Spiraget®” Insulation Gaskets Type “D” for Ring Gaskets

Available for use in ANSI B16.5, API, BS & DIN Standard In this type the gaskets available in fabric reinforced Phenolic. Available in basic “oval & octagonal” type. This type has the contact faces with oval shape. It provides a high reliability seal. These gaskets comply with ASME B – 16.20.

Materials Used

Insulation Gasket Insulation Sleeve Insulation Washer Plated Washer

Standard Neoprene faced Phenolic Reinforced Phenolic Reinforced Phenolic Electro platedsteel washer

Special Neoprene faced Phenolic Nylon Nylon -do-

-do- Mineral filledNylon Mineral filled Nylon -do-

-do- Polyethylene Polyethylene -do-

Glass Reinforced Epoxy (G-10) Glass Reinforced Epoxy (G-10) Glass Reinforced Epoxy (G-10) -do-

HEAT EXCHANGER GASKETS

Metal jacketed gaskets specially designed as Heat Exchanger Gaskets are widely used on smooth flange applications. They are ideal for Heat Exchangers, Auto claves, columns, flue stacks, boilers, gas mains, valve bonnets, pumps and similar services.

Kammprofile gaskets used as Heat Exchanger Gaskets consists of a metal core with concentric grooves on either side with sealing materials. The Sealing layers (depending on the service duty) can be Graphite, PTFE (Teflon), CAF or Metal (e.g. Aluminium or Silver). Kammprofiles can be used without sealing layers to provide an excellent seal but there is a risk of flange surface damage.

The Very wide seating stress range (minimum to maximum stress) of the Kammprofile gasket makes it

Highly suitable for varying temperature and pressures.

Less sensitive to assembly faults

Suitable for light and heavily constructed flanges.

Depending on layer material Kammprofile gaskets are resistant to temperature upto 1000° C

Resistant to media pressures upto 250 bar

When assembled the layer thickness of the sealing material is extremely small (0.5mm) thus reducing leaks, reject rates and environment pollution.

The gasket will not damage the flange surface and can be easily removed

Kammprofiles will not damage the flange faces even at extreme seating load.

Excellent performance when subject to fluctuating temperature and pressures.

Direct replacement for existing gaskets. No special flange finish is necessary.

Double Jacketed Gasket

Double Jacketed Gasket

Prev

Next

CLADDING METAL

Soft Iron, Low carbon steel, Monel Aluminium, Copper, Brass, Cupronickel 90%/10%, 70%/30%, Inconel 600,800 and different grades of Stainless Steel.

FILLER

Common filler materials used are Asbestos mill board, CAF, Non asbestos, PTFE and Grafoil. We have adequate capacity to produce any shape and size with many compartmental ribs out of different materials for heat transfer equipment, coolers, condensers, joints etc.Heat Exchanger gaskets are more compressible than sole-metal corrugated types and offer better compensation for flange irregularities when high pressures are to be sealed.

KAMMPROFILE GASKETS

Kammprofile gaskets consist of a metal core (generally Stainless Steel) with concentric grooves on either side with sealing materials. The sealing layers (depending on the service duty) can be Graphite, PTFE (Teflon), CAF or Metal (e.g Aluminium or Silver). Kammprofile’s can be used without sealing layers to provide an excellent seal but there is a risk of flange surface damage.

The very wide seating stress range (minimum to maximum stress) of the Kammprofile gasket makes it

Highly suitable for varying temperatures and pressures.

Less senstive to assembly faults (inaccurate bolt tensioning).

Suitable for light and heavily constructed flanges.

Dependent on layer material Kammprofile gaskets are resistant to temperatures up to 1000 0C.

Resistant to media pressures up to 250 bar.

gm _lor

Kammprofile Gaskets

Prev

Next

The additional benefits are

When assembled the layer thickness of the sealing material is extremely small (0.5mm) thus reducing leaks, reject rates and environment pollution.

The gasket will not damage the flange surface and can be easily removed.

Reduces maintenance costs.

Emergency sealing of damaged flanges by using 1mm thick sealing layers until the flange can be reworked.

Flange face protection Kammprofiles wil not damage the flange faces even at extreme seating load.

Excellent performance when subject to fluctuating temperatures and pressures.

Direct replacement for existing gaskets. No special flange finish is necessary.

Eco-friendly by significantly reducing leakage into the atmosphere.

Flange surface Finish

The recommended flange surface finish for Kammprofiles with sealing layers is from 125-250 RMS.

Loose or Integral rings

Thermal-shock conditions may damage Kammprofiles with integral centring rings (thermal tension may cause cracks in the core).

SEALING LAYER MATERIALS AND SEALING STRESSES

The following table gives information regarding different types of materials offered as sealing layer materials by IGP. Also given is recommended seating stress range for reliable and effective performance:

Material Temp (Deg.C) Max.Operating

Pressure(Bar) Gas Tightness Application Seating Stress

Min Max Min (N/mm2) Optimum (N/mm2) Max (N/mm2)

Graphite -200 550 250 Good Aggressive Media 20 90 400

PTFE 200 250 100 Good Aggressive Media 20 90 400

CAF -150 450 100 Moderate Liquids 65 161 400

Silver -200 750 250 Good Aggressive Media 125 240 450

MONOLITHIC INSULATION JOINTS

Monolithic insulation joint is a boltless structure that provides electrical resistance between the pipeline sections and adjoining structures, thus improving the effectiveness of the Cathodic Protection System (CP systems).

VALVE INTERNALS DIVISION PRODUCTS

Balls and Seat Rings for Ball Valves

Sizes : Upto 12”

Rating : 150# to 2500#

Material of Construction (Typical):

- Austenitic Stainless Steel

- Duplex Steel

- High Nickel Alloys (SMO 254, Inconel, Incoloy)

- Monel

- Hastalloy (C-22,C-276 etc) Etc.

Special Treatments

IGP has arrangements to supply Balls in finished and ready to use condition with stellite overlay (Stellite 6 | Stellite 12 or Stellite 21) and with Tungsten carbide coating.

Dedicated sources/Special arrangements for all above operations.

Balls and Seat rings

Balls and Seat rings are cast at our own state of the art centrifugal casting foundry located near Chennai.

We also have our own Heat treatment facility to perform Heat treatment cycles with close controls (Austenitizing | Water quenching | Annealing | Normalizing | Stress Relieving | Tempering etc.)

IGP ENGINEERS PVT LTD,

No 79, Valmiki Street,

Thiruvanmiyur,

Chennai – 600 041.

+91-44-24420608

+91-44-24424804

igp@igpindia.com

http://www.igp-group.com/home.php

You may also be interested in this gasket manufacturer:

One thought on “IGP Engineers”