Fenner Conveyor Belting Pvt Ltd is a member of Fenner Dunlop Conveyor Belting Worldwide, a division of Fenner PLC, the world’s leading manufacturer of conveyor belts for mining and industrial applications.

First launched in the 1950s and developed continuously ever since Fenaplast is Fenner Conveyor Belting Pvt’s flagship product. Our extensive knowledge of conveyor belt applications, fabric weaving, and polymer technology are combined in this market-leading range that has been at the forefront of development for over half a century.

Fenaplast solid-woven (monoply) belting, the first choice of countless mines throughout the world, has a number of significant advantages including

- fire resistant and anti-static properties which meet the most stringent safety standards in the world

- greater flexibility than press-manufactured belts, making it easier to trough and track when installed

- a solid woven one-piece carcass with no risk of ply separation

- covers which form an integral bond preventing any form of belt delamination

- high resistance to longitudinal tears

- high dynamic and static vulcanized joint properties

- excellent retention of mechanical fasteners

- high resistance to impact damage

- impervious to attack from acid, water, oil, bacteria, and chemicals

- high resistance to edge wear

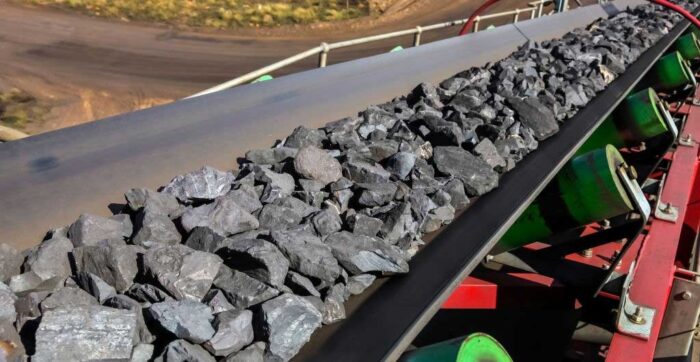

Conveyor Belts for Mining

The Fenaplast solid woven conveyor belts range is the preferred choice throughout much of the global mining industry and other industrial applications in which damage and impact resistance, in combination with premium fire resistance and anti-static properties, are key criteria in the selection of conveyor belting.

Customized Fenaplast

SPECIAL CARCASS PROPERTIES

Fenaplast carcass designs can be customized to include one or more of the following features

- increased fastener holding efficiency for high speed/tonnage applications

- improved lateral stability to further enhance resistance to longitudinal splitting on high capacity/deep trough conveyors

- high tear and rip resistance for arduous applications where belts are difficult to align and maintain

- additional carcass mass to allow belts to negotiate small radius catenary curves which would normally require a steel cord belt (to prevent the belt lifting off the structure under no-load conditions)

- the ability to operate at temperatures well in excess of 90°C (the normal limit for standard constructions)

- improved edge wear protection for extensible and similar applications

Fenner Conveyor Belting Pvt Ltd

Madurai – Dindigul Road,

Nagari, Madurai, 625 221

Tel: 91 (0) 452 2464201 (3 lines) Fax: 91 (0) 452 246420

https://www.fennerdunlopindia.com/home.html

You may also be interested in this manufacturer:

2 thoughts on “Fenner Conveyor Belting”