Hitron, a family-owned closely held company that was incorporated in 1996, commenced production of coated seeds / halogenated powder for the dry dressing of seeds. Subsequently, it was converted into a liquid formulation and the test verified its effects. The liquid formulation showed better effects on the physiological quality of seeds. With a view to invigorate the seeds further, they included the botanical extracts and protein-cum-mineral rich preparations into the formulation.

POLYMER COATED SEEDS

Paddy & Hybrid Rice, Bajra, Green Gram, Maize, Cotton Hybrid, Tomato, Sorghum, Bhendi, Sunflower, Chilli, Soybean, Bitter Gourd, Radish, Beans, Sugarcane

Features

- Free Radical Quenching: Halogenated polymer extend the shelf life of seeds through free radical quenching.

- Binding: Excellent binding to hold the agrochemicals and to minimize shedding.

- Herbal Extracts: Herbal extracts augment seed vigor and viability.

- Safeguarding genetic purity

- Enable cultivar/Hybrid/Parental identification

- Seals seed coat cracks, Reduces seed moisture exchange

- Ensure early and higher field stand

- Improved Vigour & Viability

- Smooth & Coloured surfaces reduce infection & infestation

- Enriched antioxidants through herbal extracts

- Holds agro-chemicals uniformly

- Aesthetics: They also customize colors of your liking.

Off late, to match the present-day needs of the seed industry, they amalgamated two more constituents into the formulation, namely, a good polymer (for binding) and seed-friendly colors (for aesthetic look) through scientific testing. Thus, the present formulation is transformed into a 3-in-1 product, where the halogenations process, herbal extracts, and the proteins-cum-minerals take care of the seed quality, the polymer binds the agro-chemicals and the colors impart an aesthetic look to the seeds making it a unique product in the market.

Hitron Bio Seed Coating Private Limited was exclusively incorporated to cater to the export market with a 100% EOU license from the government of India and in order to comply with International requisites of the Industry.

A state of art production facility for herbal extract and polymer formulation is installed in the licensed plant to manufacture 400 Metric Tons of polymer per annum.

A research laboratory with a controlled germination facility along with a fully equipped R&D center has been set up to conduct more scientific studies.

SEED DETERIORATION, a serious problem in the seed industry.

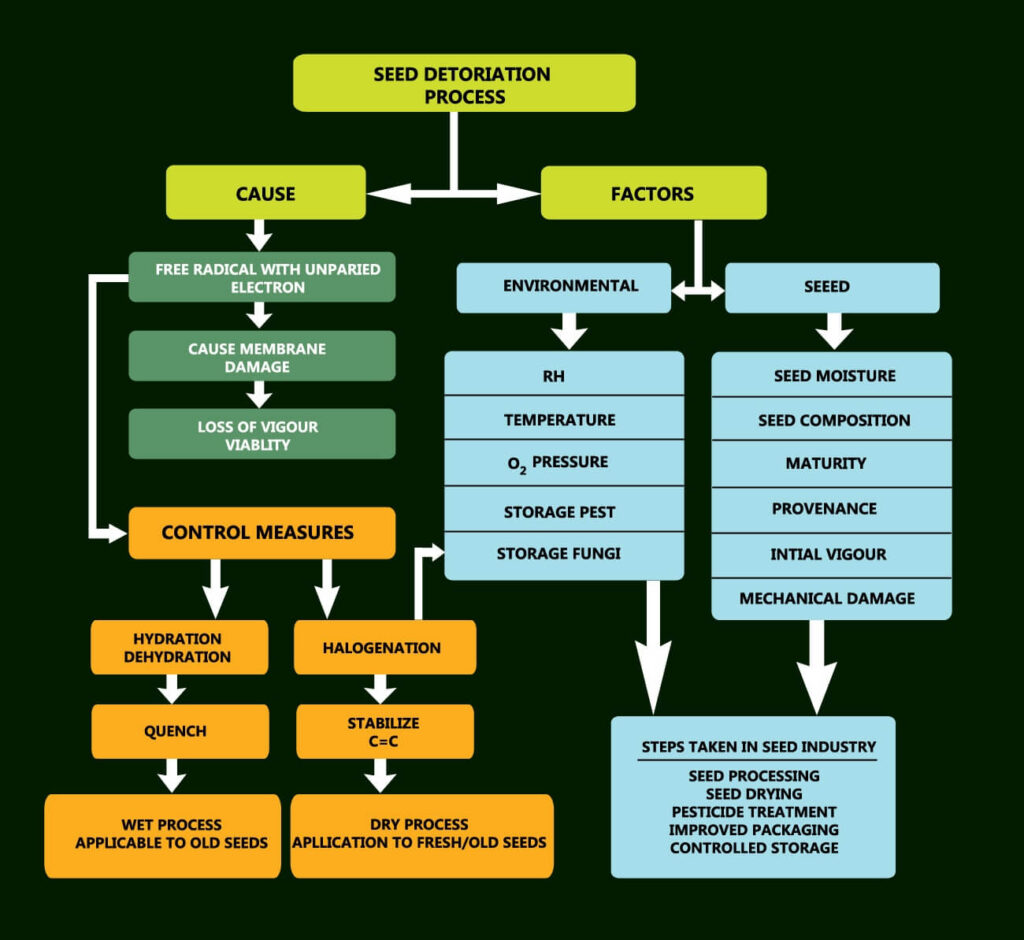

Seed Deterioration is a biological process that cannot be stopped or reversed but the reduction of cellular damages caused during seed storage will decelerate the speed of seed deterioration.

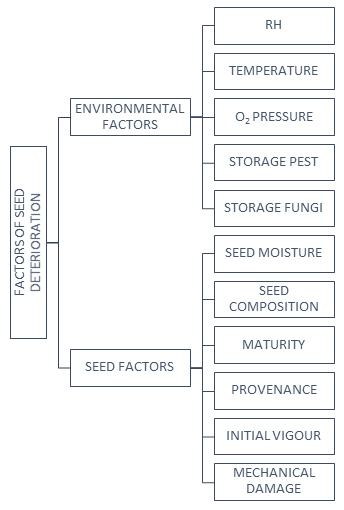

The factors of seed deterioration listed below are well addressed with modern techniques and preventive measures to safeguard the precious seeds:

Nevertheless, the cause for seed deterioration is not just these factors.

‘Free Radicals’ (FR) as the cause of seed deterioration was propounded by Prof. R.N. Basu, which is widely accepted. He developed Hydration – dehydration (H-DH) treatment to quench the ‘FR’. He and his team of students standardized the various aspects and established its beneficial effect. The treatment given to seeds in the mid-way of storage effectively controlled the deterioration process and helped to maintain high vigor and viability during the subsequence storage of seeds. In spite of the best results, this treatment was not adopted on large scale by the seed sector due to practical difficulties encountered to follow the treatment procedure with a bulk quantity of seeds.

In the early ’90s, seed scientist prof. Dr.C.Dharmalingam, through his 35 years of continuous research on seed aging, evolved a process that was industrially feasible and a very effective methodology to reduce the free radical production by strengthening the C=C (double bond) through halogen vapors by which the radicals were made more stable for oxidative changes and reduce the production of FR. This Halogenation process has proved to be very effective.

The halogenated seeds triggered the in situ vigor and viability and helped to maintain almost the same level during subsequent storage. This treatment can be given both to harvest-fresh and stored seeds with good benefits. Research studies carried out in different kinds of halogenated seeds yielded reproducible results with higher germination, seedling vigor, field stand, and higher productivity

For the past 10 years, around 6 seed scientists apart from 8 Ph.D. and 15 M.Sc (Ag.) students have worked in different agricultural and horticultural seeds through various schemes and published their confirmative results.

The reproducible results achieved over a decade of research in the laboratory and in on-farm trials on various crops in Tamil Nadu and at the National level enabled the Tamil Nadu Agricultural University and National Seed project of ICAR to recommend this product for adoption by seed producers and farmers to save their valuable seeds.

Hitron Bio Seed Coating Private Limited

Manufacturer of Coated Seeds

S.F No: 484,

Behind Kumar Polycot Mill,

Thudiyalur-Kovilpalayam Main Road,

Idigarai, Coimbatore – 641022,

Tamilnadu, India

+91 96004 11553,

+91 99524 21880

santhosh@hitronbsc.com

You may also be interested in this manufacturer of seeds:

One thought on “Hitron”