Passaro International is a leading supplier and provider of high-quality Rotary Vacuum Drum Filters (RVDF) and their associated spare parts. With a strong commitment to excellence and a proven track record in the field of industrial filtration, Passaro International offers a comprehensive range of RVDF equipment and components to meet the diverse needs of its global clientele. As a trusted source for reliable filtration solutions, Passaro International combines a deep understanding of process filtration with a dedication to customer satisfaction, making them the preferred choice for businesses seeking efficient and dependable rotary drum filtration systems and their essential spare parts.

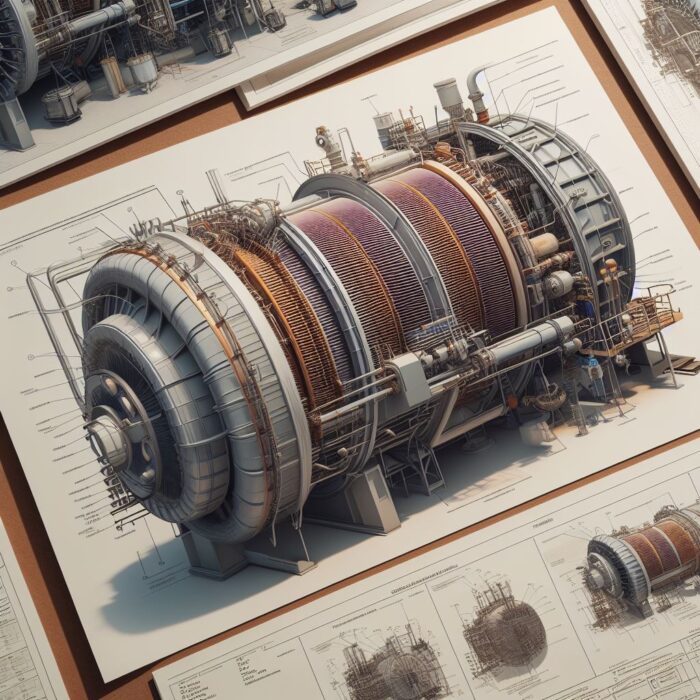

Rotary Vacuum Drum Filters

EIMCO-K.C.P. Continuous vacuum drum filters are versatile filters designed to handle a wide range of slurry types, making them suitable for various applications. These vacuum drum filters offer superior solid-liquid separation compared to other mechanical dewatering filters. They are less reliant on specific gravity differences for achieving clarity and are less prone to disruptions caused by process variations.

EIMCO-K.C.P. drum filters are known for their high filtration rates and effective washing capabilities. They offer flexibility in cycle times to ensure optimal cake formation, dewatering, and washing for different applications. These filters excel in scenarios where cake washing is necessary, where a uniform cake deposit on the filter media is desired, or when discharging the cake is challenging.

There are five basic discharge types for these filters:

- Scraper Discharge: In this method, a scraper blade is used to remove the cake from the filter medium, with cake dislodged by an air blowback. The scraper directs the cake into the discharge chute, but it doesn’t come into direct contact with the filter medium. This discharge type is suitable for heavy solids and typical slurries.

- Belt Discharge: The filter employs a fabric belt that is removed, washed, and returned to the drum. An aligning device keeps the belt wrinkle-free during its travel. This discharge method is ideal for thin cakes of difficult, slightly soluble solids.

- String Discharge: This method uses endless strings or wires spaced apart and tangentially separated from the drum at the point of cake discharge. The strings lift the cake off the drum, and if the cake has the right consistency, it can be much thinner than what drum filters typically handle. This method is often used in starch and pharmaceutical industries.

- Roller Discharge: A roll in close proximity to the drum at the point of cake discharge rotates in the opposite direction at a peripheral speed similar to or slightly faster than the drum. It’s effective for thin, sticky cakes and can be aided by a slight air blow if needed.

- Pre-coat Discharge: Pre-coat drum filters are coated with a layer of diatomaceous earth or a similar material. During operation, a clear filtrate is obtained, and when vacuum is applied, the liquid is drawn through the pre-coat material, and solids are removed by a scraper blade as the drum rotates. Pre-coat filters are recommended for applications where small amounts of solids need to be removed from large liquid volumes, for clarifying or polishing effluent, or when producing a high-quality filtrate is crucial.

These EIMCO-K.C.P. drum filters offer a wide range of options for different industries and filtration needs.

Passaro International

Chennai.

sales@passarotrading.com

https://www.passarotrading.com

You may also be interested in this supplier of spares for Horizontal Vacuum Belt Filter.