Mold Masters is a global leader in hot runner injection molds, temperature controllers, auxiliary injection, and co-injection systems. They deliver the best performance that optimizes production by enhancing molded part quality, increasing productivity, and lowering part cost. Mold-Masters services customers in 100 countries with over 2,100 employees.

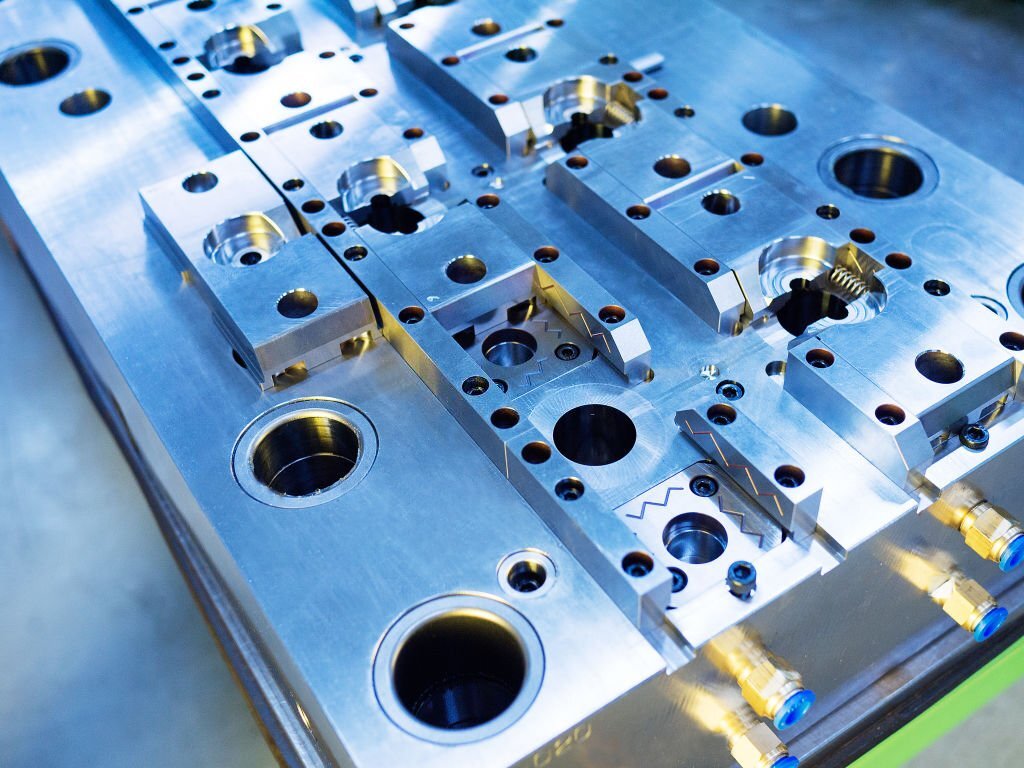

Hot Runner Injection Molds

Master-Series

THE BENCHMARK IN HOT RUNNER PERFORMANCE AND RELIABILITY

Proven to deliver consistent high performance processing capabilities for exceptional part quality. Compatible with a wide range of resins, Master-Series is the ideal choice for almost any application across any industry.

Master-Series Nozzles

- Industries broadest nozzle range.

- Excellent thermal profile (10% max variation*).

- Enhanced process control and repeatability.

- Produces high quality parts and minimizes scrap.

- Serviceable from the parting line.

Brazed Heater Technology

- Full heater contact optimizes heat transfer.

- Superior system thermal balance.

- Exceptional reliability minimizes downtime.

- Eliminates spare heater costs.

iFLOW Manifold Technology

- Best in-class melt management.

- Industry leading mold fill balance.

- Rapid color change performance.

- Extensive flexibility for design optimization.

- Patented melt flow geometry, flow path options and runner shapes.

Energy Efficient

- Up to 27% (avg.) lower power consumption than competitive systems.

Industry’s Best Warranty

- Available 10 year coverage.

Summit-Series Hot Runner Injection Molds

CLIMBING TO NEW PERFORMANCE HEIGHTS

The industry’s latest advancement in hot runner technology delivering peak performance and ultimate precision. Ideal for molding with today’s challenging abrasive, corrosive, shear and temperature sensitive resins like PC, POM & PBT. Summit-Series is critical for demanding Medical, Personal Care and Technical molding applications.

Summit-Series Nozzles

- Superior thermal profile (5% max variation*).

- Ideal for molding shear and temperature sensitive resins.

- Exceptional process control and repeatability.

- Produces high quality parts and minimizes scrap.

- Serviceable from the parting line.

Full Stainless-Steel Construction

- Greatest resistance to corrosive and abrasive resins.

- Helps prevent contamination defects from premature wear.

- Extends service life.

iFLOW Manifold Technology

- Best in-class melt management.

- Industry leading mold fill balance.

- Rapid color change performance.

- Extensive flexibility for design optimization.

- Patented melt flow geometry, flow path options and runner shapes.

- Reduced stack height.

Brazed Heater Technology

- Full heater contact optimizes heat transfer.

- Superior system thermal balance.

- Exceptional reliability minimizes downtime.

- Eliminate spare heater costs.

EcoDisk Ceramic Pads

- Standard in all Summit-Series systems.

- Provides greater thermal stability.

- Reduces energy consumption by up to 29% (vs. steel pads).

Industry’s Best Warranty

- Available 10 year coverage.

Accu-Line Hot Runner Injection Molds

EASY, ECONOMICAL SINGLE CAVITY VALVE GATING

An advanced inline design proven to deliver consistent high performance processing capabilities for exceptional part quality. Available with the broadest shot range capacity and widest range of resin compatibility. The ideal choice for high volume production or prototyping, of the smallest to largest parts, with applications across any industry.

Fully Integrated In-Line Manifold Design

- Reduces mold backing plate thickness by up to 67%.

- Valve gated for larger process window.

- Greater durability vs. off-centre designs.

- Large runner profile improves resin flow.

- Incorporates high temperature Viton seals.

- Reliable leakage protection.

Single Zone Heated Body

- Superior thermal uniformity.

- Enhances molding process control.

- Improves part quality.

- Minimizes scrap.

Water Cooling Channels

- Hose or Direct Mold Connection.

- Minimizes component misalignments from heat expansion.

- Maintains system integrity.

- Ensures long term reliability.

Brazed Heater Technology

- Superior reliability maximizes uptime.

- Eliminate spare heater costs.

- Energy efficient.

Velocity LS Hot Runner Injection Molds

CONFIGURABLE HOT RUNNERS, DELIVERING PERFORMANCE AND VALUE, FAST

The hot runner system that can be combined with a wide range of popular standard 1-8 drop manifold configurations. Allows simple projects to get off the ground faster and more economically. Inject Velocity into your next project and bring your business up to speed.

Highly Configurable

- One of the most configurable standardized systems in its class.

- Largest shot range.

- Available as a manifold or hot half system.

High Performance

- Excellent nozzle thermal profile (10% max variation*).

- Optimized melt channels specific to each application.

- Consistent high quality molded parts.

Fast Delivery

- Immediate drawing availability through our online configurator.

- Complete systems shipped in as little as 3 weeks.

Superior Value

- Performance and reliability at an economical price.

Industry’s Best Warranty

- Available 10 year coverage.

Sprint

LIGHTNING FAST, SPECIALIZED CAP & CLOSURE SYSTEM

Sprint hot runner systems are specifically engineered for caps and closure applications. Optimized for reliable high speed molding, Sprint systems are capable of <2 second cycle times, fast color changes and low energy consumption. A range of special features ensures highest production quality while minimizing downtime. Now includes MasterSHIELD Technology as standard for enhanced leakage protection.

Sprint Nozzles

- Excellent thermal profile (10% Max Variation*).

- Enhanced process repeatability.

- Produces high quality parts and minimizes scrap.

- NEW MasterSHIELD Technology for enhanced leak protection.

NEW Sprint Color Change Tips

- Clears color up to 47% faster.

- Precise gate vestige.

- Industry standard gate cut-out.

- Accessible from the parting line.

iFLOW Manifold Technology

- Best in-class melt management.

- Industry leading mold fill balance.

- Rapid color change performance.

- Extensive flexibility for design optimization.

- Patented melt flow geometry, flow path options and runner shapes.

- Reduced stack height.

Brazed Heater Technology

- Superior thermal balance.

- Enhances rheological balance.

- Exceptional reliability minimizes downtime.

- Eliminate spare heater costs.

Industry’s Best Warranty

- Available 10 year coverage.

ThinPAK-Series

THE SPECIALIZED HOT RUNNER SYSTEM FOR HIGH PRESSURE THIN WALL PACKAGING

The best solution for producing exceptional high quality thin wall packaging products from small in-mold labeled containers to large pails. Incorporating new MasterSHIELD Technology, ThinPAK-Series has the strength and durability to mold with complete reliability in high pressure applications up to 2,800 Bar. Compatible with PP, PS and other resins.

New ThinPAK Nozzles

- Precisely balanced thermal profile.

- Excellent process control and repeatability.

- High molded part quality.

- Serviceable from the parting line.

New ThinPAK Manifold

- Exceptional strength and reliability.

- 40% higher pressure limit than our standard manifold designs.

- Ideal for high pressure thin wall applications.

New MasterSHIELD Technology

- Reliable leakage protection even on cold start-ups.

- Helps eliminate unscheduled interruptions.

- Minimizes maintenance and service interval requirements.

- Mold with confidence and complete peace of mind.

Brazed Heater Technology

- Precise thermal balance and control.

- Superior reliability maximizes uptime.

- Eliminate spare heater costs.

- Energy efficient.

Industry’s Best Warranty

- Available 10 year coverage.

Fusion-Series G2

DROP-IN, CONNECT AND INJECT

A completely pre-assembled and pre-wired system which allows for quick and easy one step drop in installation and connection. Ensures your mold is back into production as quickly as possible. Focused on high quality economical production of medium to large parts it is the ideal system for automotive, appliance, logistic and many other similar applications.

Completely Pre-Assembled

- Fast, one-step installation.

- Requires up to 70% less time to assemble and install.

- Delivered pre-wired, pre-plumbed and tested.

Integrated Wire Armour

- Protects and routes all lines.

- Acts as a stable mounting platform for plumbing.

- Reduces plate machining requirements.

Fusion-Series G2 Nozzles

- Precise thermal profile.

- Multiple heater zones for enhanced thermal control of extended nozzle lengths.

- Field replaceable heaters minimize downtime.

- Threaded nozzle base available for enhanced leak protection.

Global Support Network

- Technical and Field support.

- Optimization services minimize risk.

- Faster and more precise mold integration.

- Rapid spare parts supply.

FUSION-SERIES G3

DROP-IN, CONNECT AND INJECT

A completely pre-assembled and pre-wired system which allows for quick and easy one step drop in installation and connection. Ensures your mold is back into production as quickly as possible. Focused on high quality economical production of medium to large parts it is the ideal system for automotive, appliance, logistic and many other similar applications.

Completely Pre-Assembled

- Fast, one-step installation.

- Requires up to 70% less time to assemble and install.

- Delivered pre-wired, pre-plumbed and tested.

Integrated Wire Armour

- Protects and routes all lines.

- Acts as a stable mounting platform for plumbing.

- Reduces plate machining requirements.

Fusion-Series G3 Nozzles

- Precise thermal profile.

- Multiple heater zones for enhanced thermal control of extended nozzle lengths.

- Field replaceable heaters minimize downtime.

- Threaded nozzle base available for enhanced leak protection.

- NEW More compact nozzle bore

- NEW Cold installation

Global Support Network

- Technical and Field support.

- Optimization services minimize risk.

- Faster and more precise mold integration.

- Rapid spare parts supply.

Dura+

THE CLEAR CHOICE FOR LENSES

The ideal hot runner system for consistent, high quality production of automotive lens components that demand exceptional clarity. Engineered to perform with today’s challenging resins it is compatible with corrosive resins such as PC, PC-ABS & PMMA. Dura+ remains the clearest choice for automotive lens molding applications.

Dura+ Nozzles

- Enhanced thermal profile.

- Maintains molded part quality and strength.

- Helps prevent resin burns.

- Excellent process repeatability.

- Pressure drop reduction by up to 27%.

Stainless Steel Construction

- Unmatched corrosion resistance.

- Helps prevent contamination defects.

- Extends service life.

Highly Polished Runner Finish

- Specifically suited for automotive lighting resins.

- Optimizes resin flow.

- Prevents imperfections and ensures highest part quality.

Field Replaceable Components

- Focused on minimizing downtime.

- Nozzle sleeve heaters (F-Style).

- Manifold flexible tubular heaters.

- Manifold heater plates.

Industry’s Best Warranty

- Available 10 year coverage.

Accu-Line FM Hot Runner Injection Molds

EASY, ECONOMICAL SINGLE CAVITY VALVE GATING

Engineered to deliver exceptional part quality with today’s challenging abrasive, corrosive, shear and temperature sensitive resins such as PC, PC-ABS and PMMA. Critical for demanding Automotive Lenses, Medical, Personal Care and Technical molding applications.

In-Line Flush Mount Design

- Buried in plates for added protection.

- Even force distribution.

- Valve gated for larger process window.

Full Stainless Steel Construction

- Greatest resistance to corrosive and abrasive resins.

- Helps prevent contamination defects from premature wear.

- Extends service life.

Brazed Heater Technology

- Excellent thermal profile (10% max variance*) for tight process control.

- Compatible with shear and temperature sensitive resins.

- Superior reliability minimizes downtime.

- Eliminates spare heater costs.

In-Press Service Capabilities

- Quickly and easily maintained.

PET-Series Hot Runner Injection Molds

THE HIGH-PERFORMANCE HOT RUNNER SYSTEM FOR PRODUCING PET PREFORMS

PET-Series incorporates new technologies and features that focus on enhancing part quality, increasing productivity and lowering part cost. PET-series hot runner systems are compatible with many industry standard layouts, existing molds and fit into all major machine platforms including those with post mold technology. Now includes MasterSHIELD Technology, as standard, for enhanced leakage protection.

NEW PET Nozzle

- Improved thermal profile.

- Field replaceable heater sleeve.

- NEW MasterSHIELD Leak Protection Technology.

- Increased service life of nozzle tip insulators.

- Low power consumption.

NEW PET Actuator

- Run cool design.

- Reduces PET dust and extends piston seal life.

- Extends service intervals and minimizes unscheduled downtime.

- Quick and easy pin access.

iFLOW Manifold Technology

- Multi-level manifold design.

- Best in-class melt management.

- Extensive flexibility for design optimization.

- Industry leading mold fill balance.

- Reduced AA levels.

Global Support Network

- Industry leading aftermarket support.

- Standard spare parts in stock and ready to ship.

Axiom Hot Runner Injection Molds

FULLY BALANCED IN-LINE SINGLE STAGE PET VALVE GATED HOT RUNNER SYSTEM

1-40 drop hot half systems designed for injection blow systems (IBS) and injection stretch blow machines (ISBM). Specifically engineered to meet the requirements of the competitive PET bottle manufacturing industry. Axiom is focused on delivering higher production quality, higher yield and reduced production costs.

Master-Series Nozzles

- Excellent thermal profile (10% Max Variation*).

- Enhanced process control and repeatability.

- Increased processing window.

- Produces high quality parts and minimizes scrap.

- Fast and simple start-up.

Advanced Valve Gated Design

- Superior gate quality.

- Decreases cycle times.

PET Dust Management Control System

- Special sealing mechanisms and venting channels.

- Significantly minimizes dust accumulation inside the system.

- Extends maintenance intervals.

- Helps prevent failures and unscheduled downtime.

Brazed Heater Technology

- Superior reliability maximizes uptime.

- Eliminates spare heater costs.

iFLOW Manifold Technology

- Industry leading mold fill balance.

- Change color up to 45% faster.

Industry’s Best Warranty

- Available 10 year coverage.

LSR Cold Deck Hot Runner Injection Molds

INDUSTRY LEADING LSR PROCESSING CAPABILITIES FROM KIPE MOLDS

Now get valve gated cold decks for precision Liquid Silicone Rubber (LSR) molding from Mold-Masters through our strategic partnership with KIPE MOLDS. KIPE brings over 40 years of highly successful LSR knowledge and experience to our customers. Your best solution for optimized processing of LSR in single shot or over molding applications across any industry.

Specialized LSR Nozzles

- Wide shot range.

- Tight pitch design.

- Optimized gate design for faster cycle times and exceptional part quality.

Integrated Water Jacket

- Accurately maintains process temperatures.

- Helps ensure highest molded part quality.

Valve Gated Designs

- Exceptional process control.

- Wider range of material viscosity compatibility.

- Long term maintenance cost savings.

Valve Gate Flow Control

- Regulate flow to enhance fill balance.

- Simply turn a dial to adjust opening stroke.

Global Network Support

- Expertise in a variety of LSR applications.

- Local spare parts and service support.

- Consultations available.

Mold-Masters

India Headquarters

Coimbatore,

Tamilnadu, India

+91 422 423 4888

http://www.moldmasters.com/index.php/

You may also be interested in these injection molding companies.